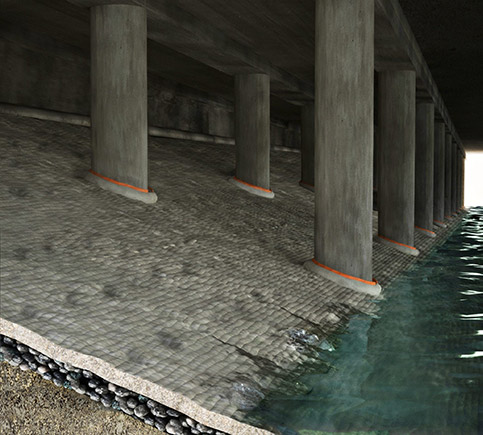

Scour Protection

Quay walls can be structurally undermined by the erosion of bed material caused by vessel propulsion. The displacement of bed material can also produce mounding, effecting clearance levels for vessels.

Concrete Mattress Solution

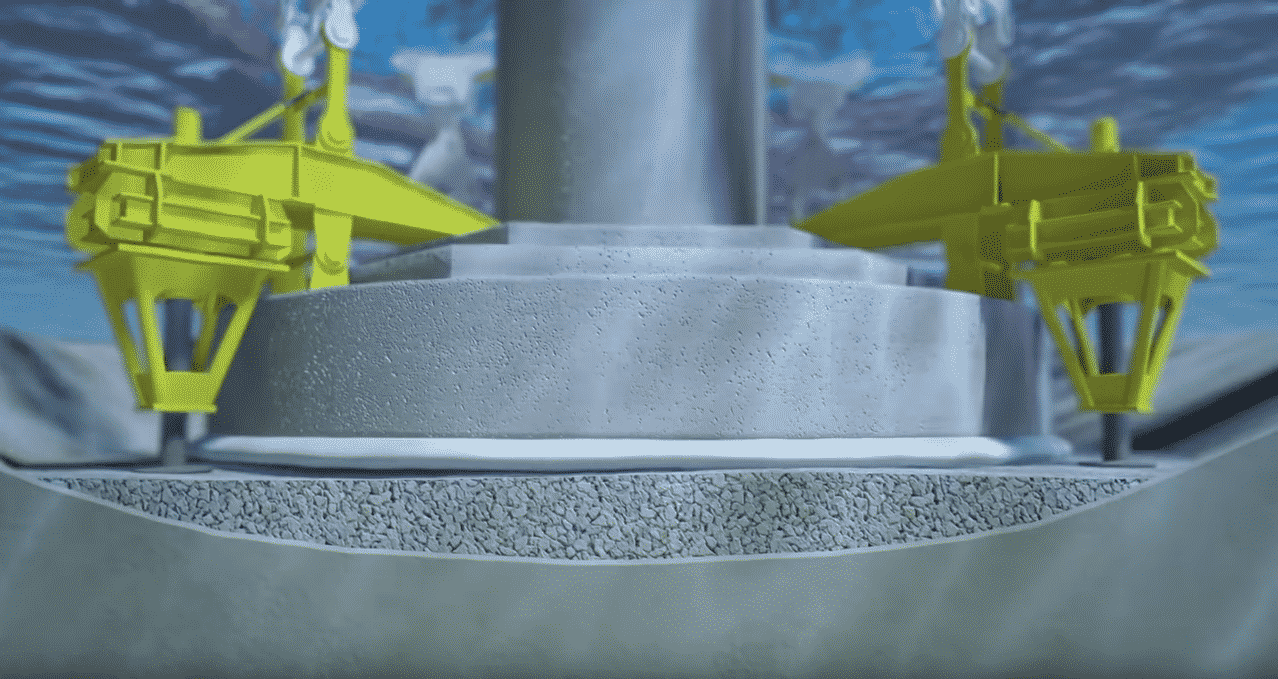

In situ concrete mattress prevents vessel scour and maximises clearance levels. The system produces a plain concrete slab of uniform thickness with fully interlocking shear joints. This creates a continuous concrete slab that seals against the quay wall and protected at the edges with rock, embedment or a formwork collapsing edge.

The plain concrete slab enables with low vessel clearance with high propulsion velocity due to effectively distributing the hydrodynamic forces across the slab produced by the vessel.

The in situ concrete mattress system has 50 years of proven usage and has a performance record of withstanding extreme action from jet flows of up to 12.5m/s. The system is typically 220 to 300mm in thickness for the protection of vertical quay walls.

Design

Proserve engineers undertake design of berth scour protection and support other engineers as required. Research scale model testing is undertaken in our in-house testing facility.

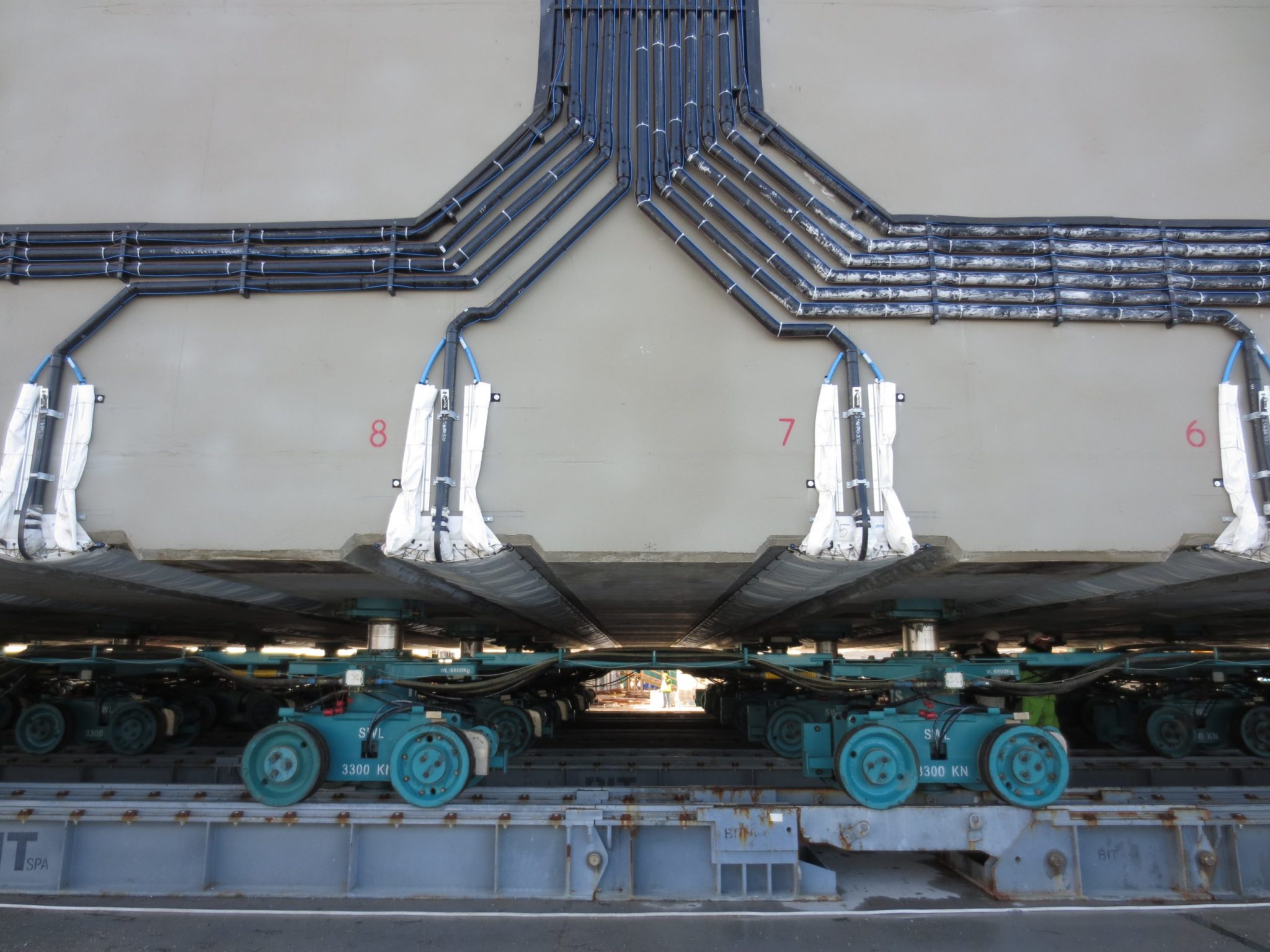

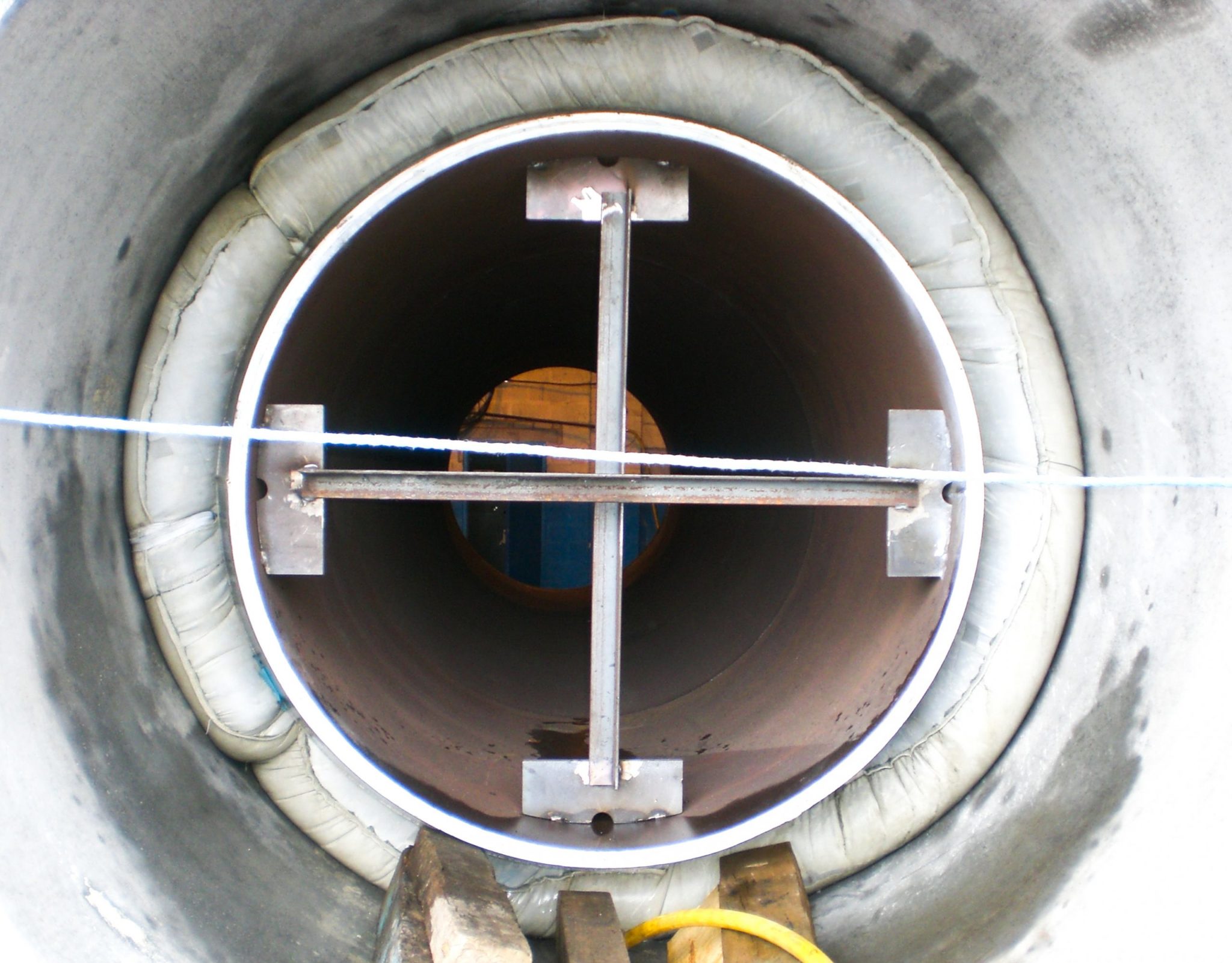

Installation

The mattress aprons are formed by divers rolling out mattress formwork underwater which is pump filled from the quay side with a 2:1 sand cement micro concrete mix 35N/mm² strength. The fluid concrete is protected against wash out during curing by the formwork.

Joints between the mattress panels are formed by divers zipping a dual connection forming ball and socket shear joints, producing the interlocked concrete slab. The system does not require expensive marine plant, due to being filled in situ, the system can be used on undulating beds and does not require precise levelling preparations. The typical installation rates per day per dive team are 125-300m² depending upon working conditions.

Advantages

Sealed Protection

- With effective joints creating a continuous concrete apron, the system is sealed against flow caused by propeller action

- Sealed systems can withstand much greater hydrodynamic forces than open systems

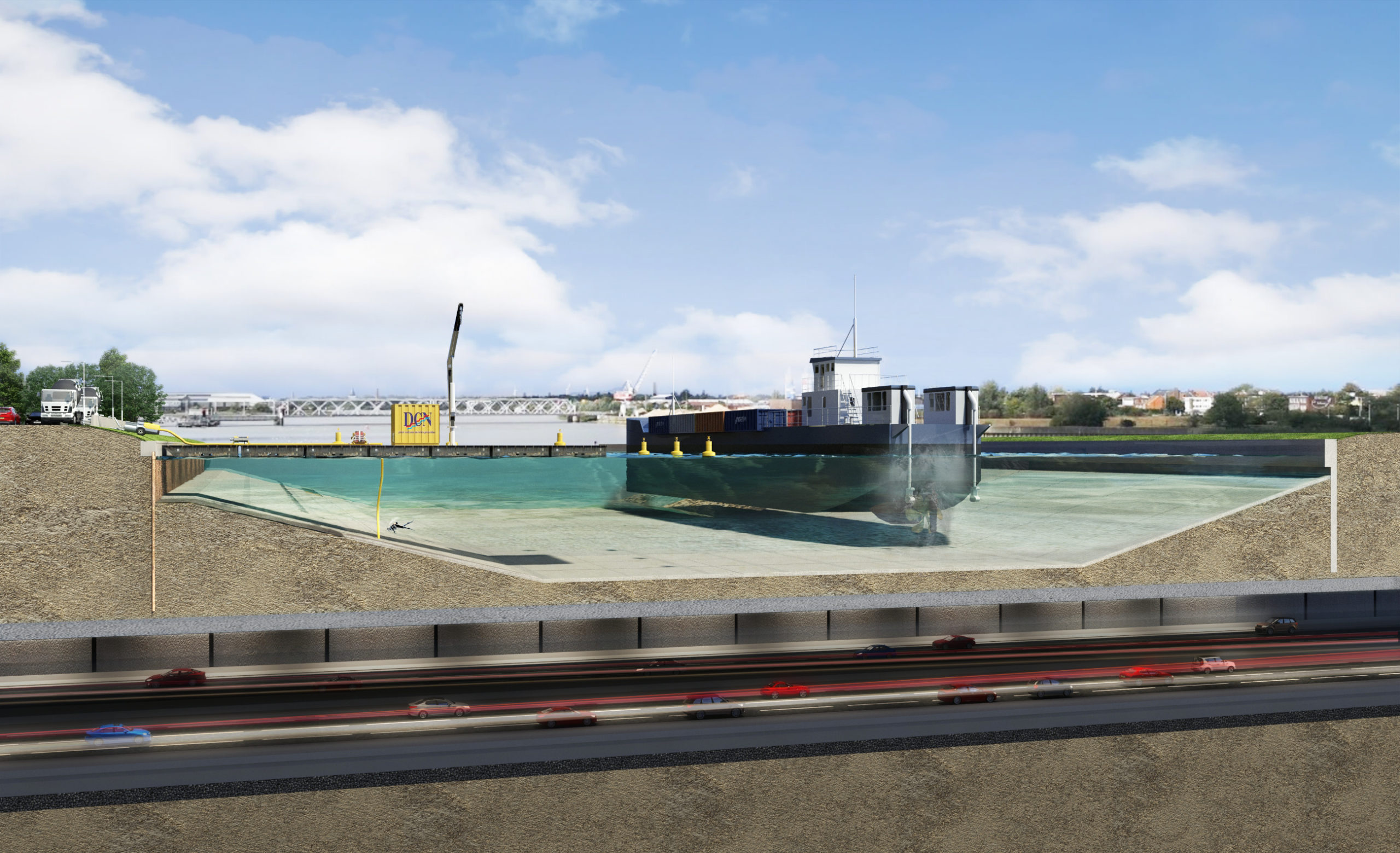

New Berths

- Reduced dredging and quay wall height

Berth Deepening

- Increased depth capacity from existing quay structure