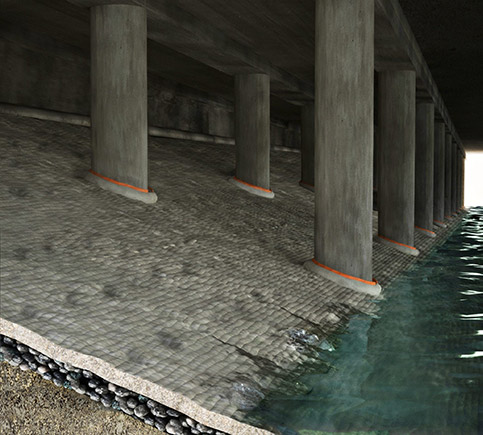

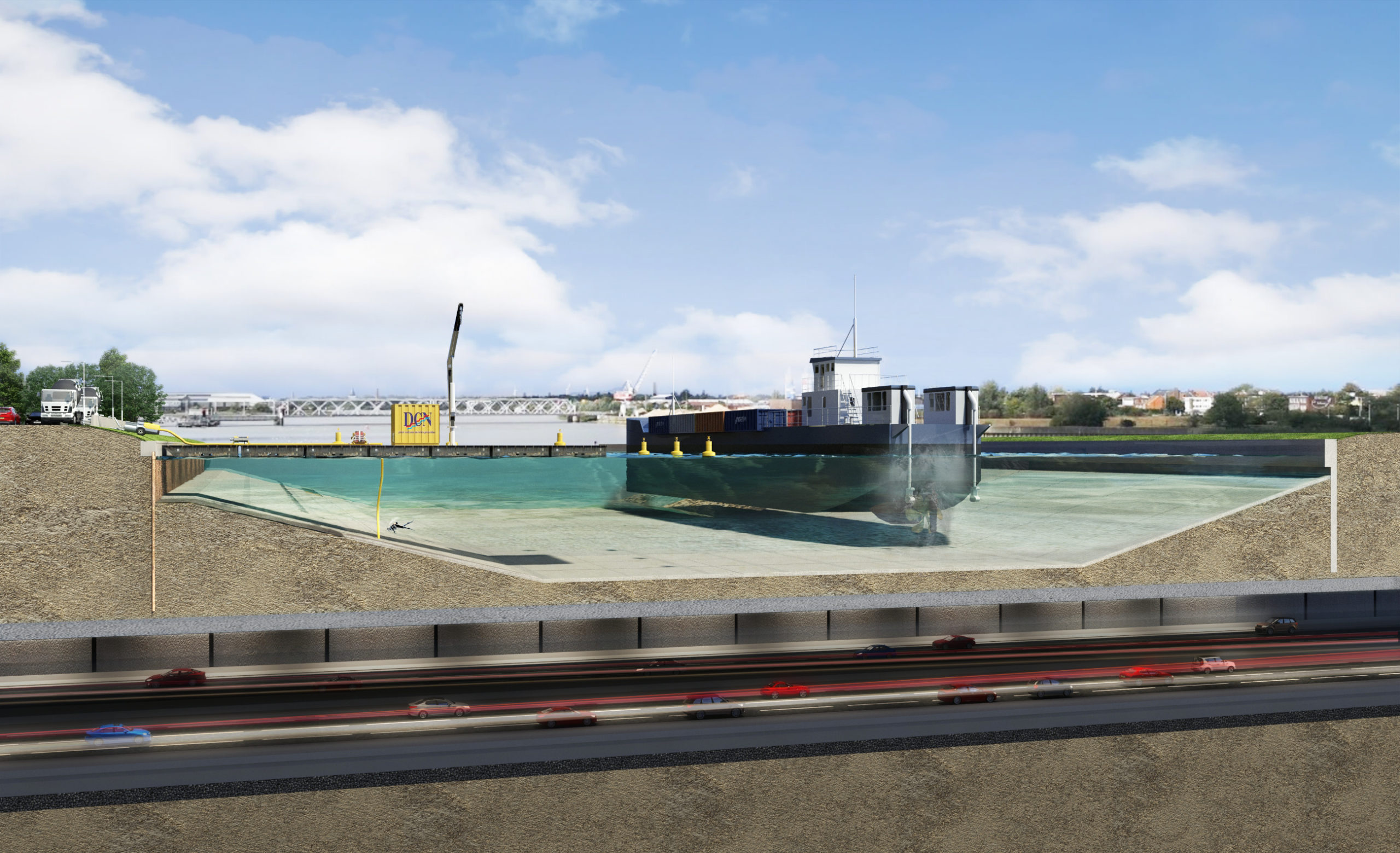

A new piled jetty for container vessels is being constructed at Port au Prince following the 2010 earthquake, when the old jetty slipped into the sea due to liquefaction.

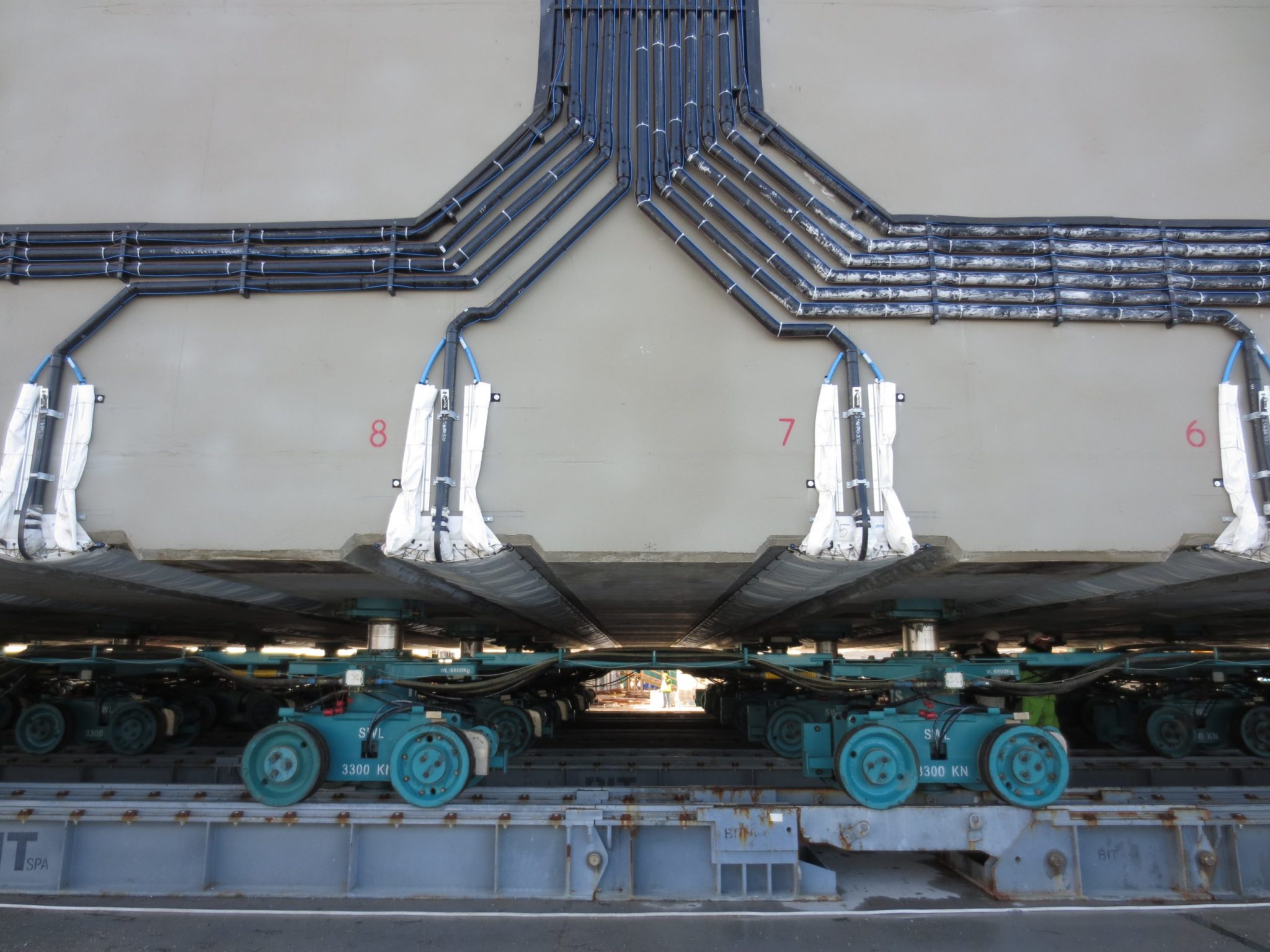

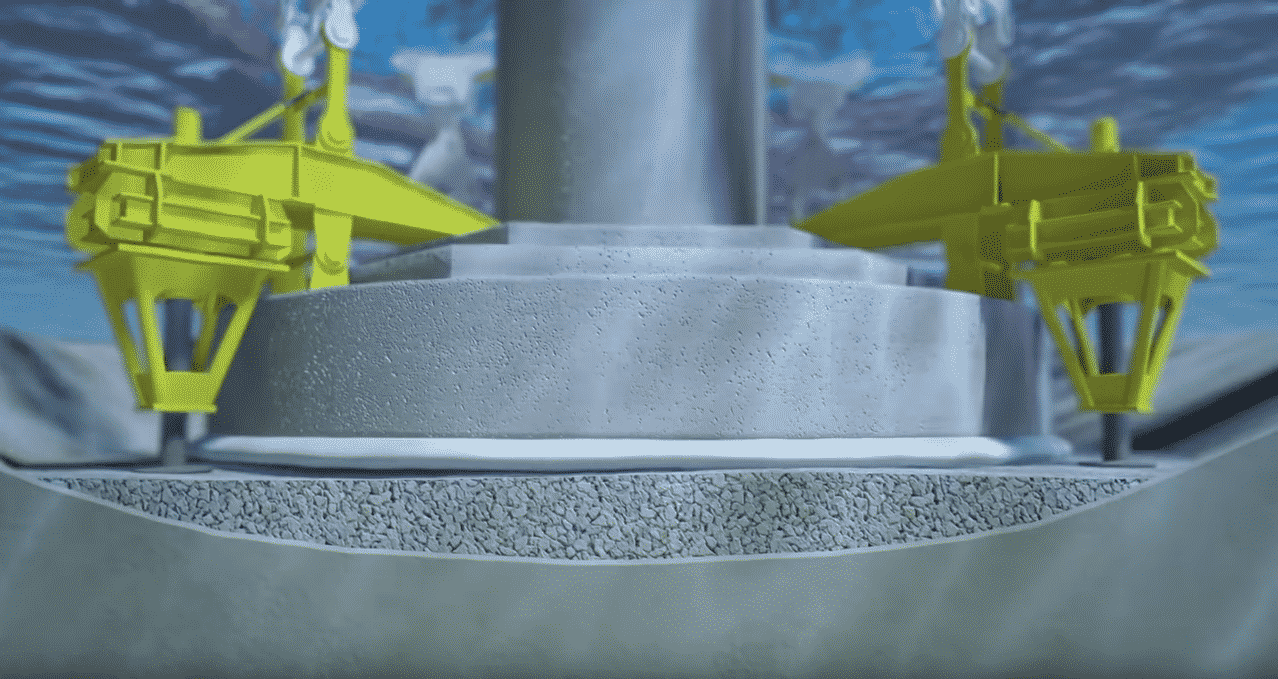

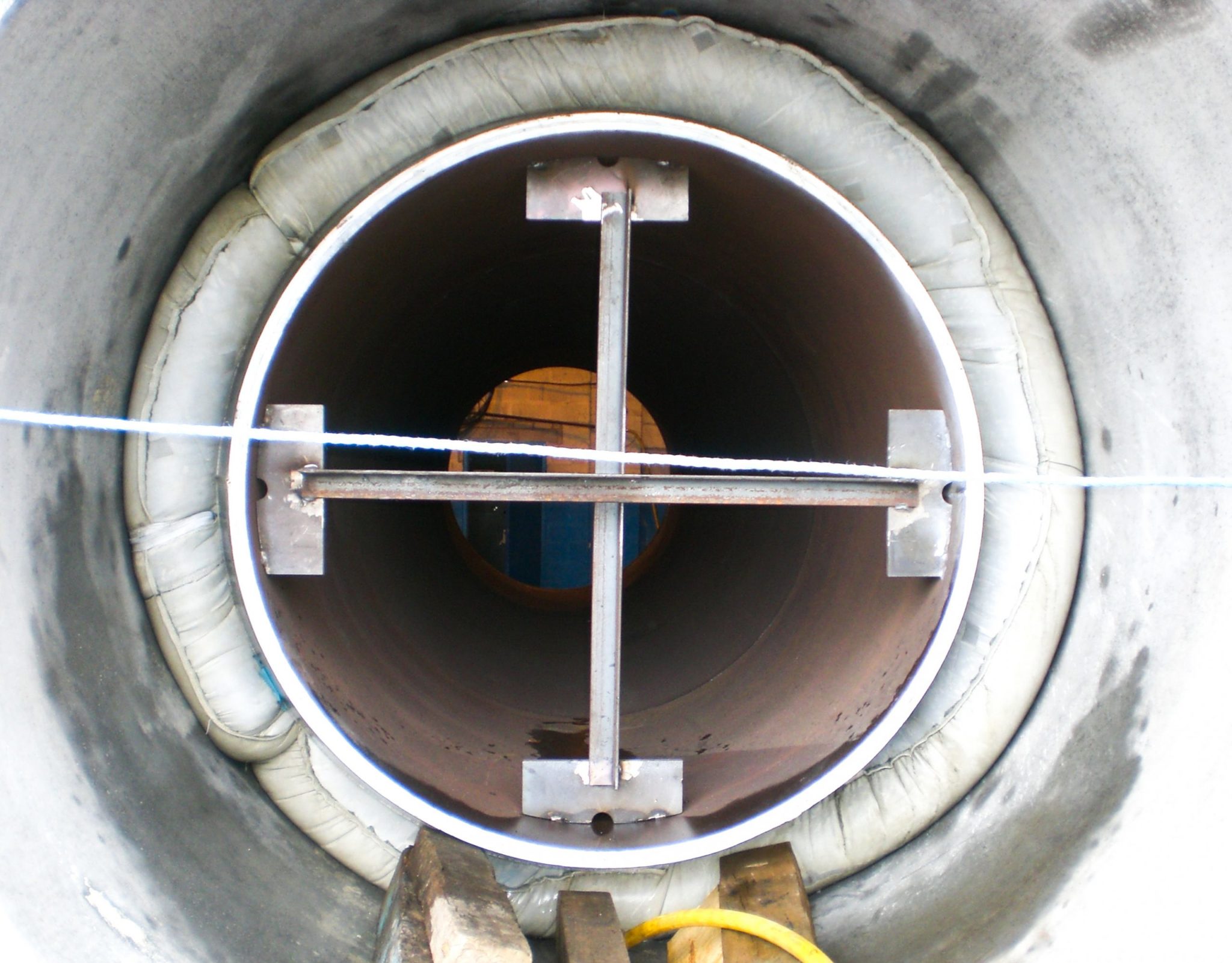

The new jetty is using a innovative construction technique. Steel shell piles are being driven by land based piling plant to save on marine piling costs and then the jetty berth and slope is dredged and excavated from land by long reach excavators working around the piles.