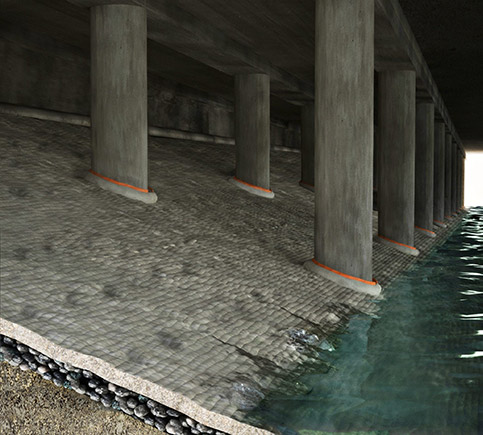

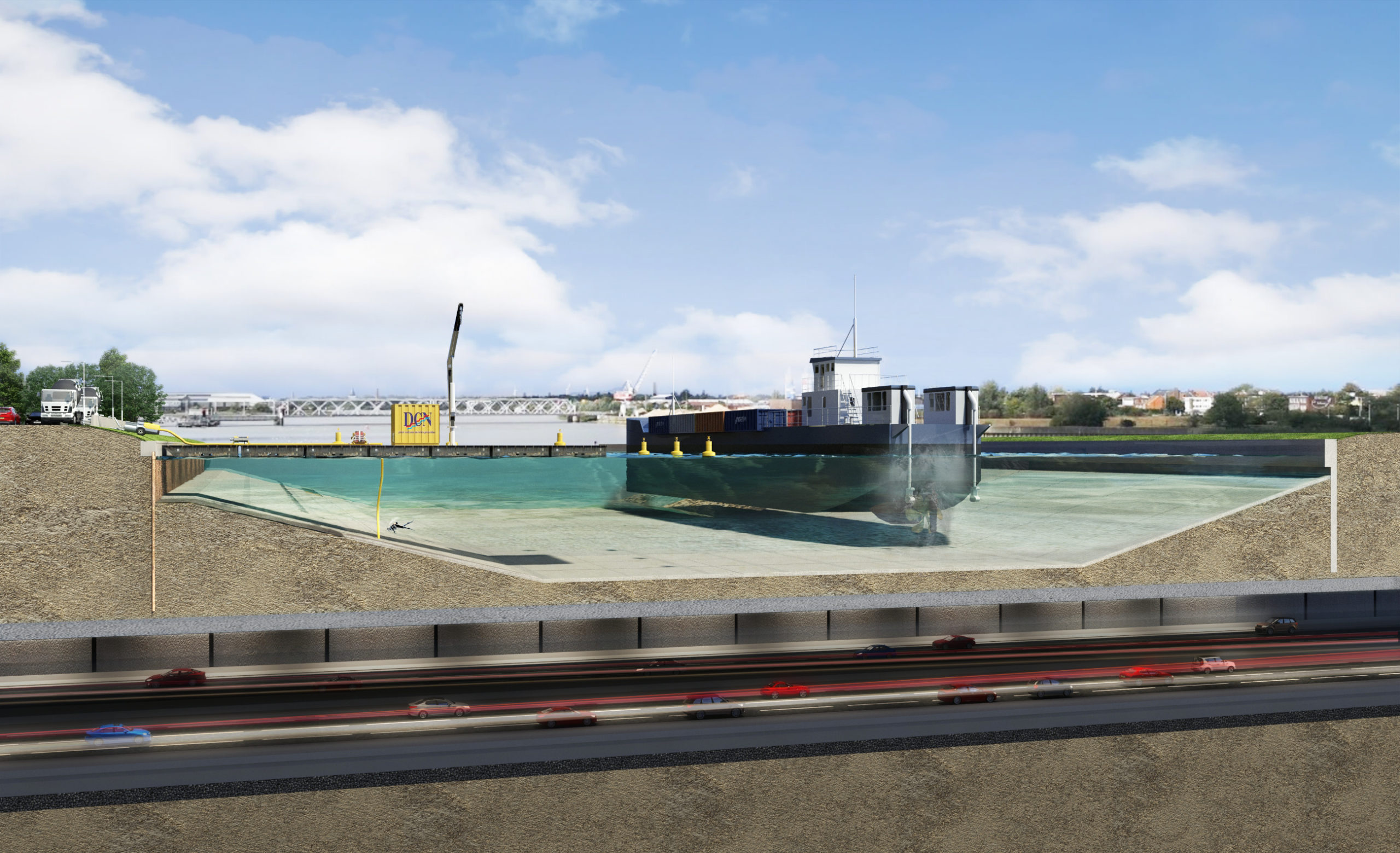

A newly constructed piled jetty at Puerto Quetzal, Guatemala requires berth scour protection to combat against vessel scour action to the slope and wave zone beneath the jetty.

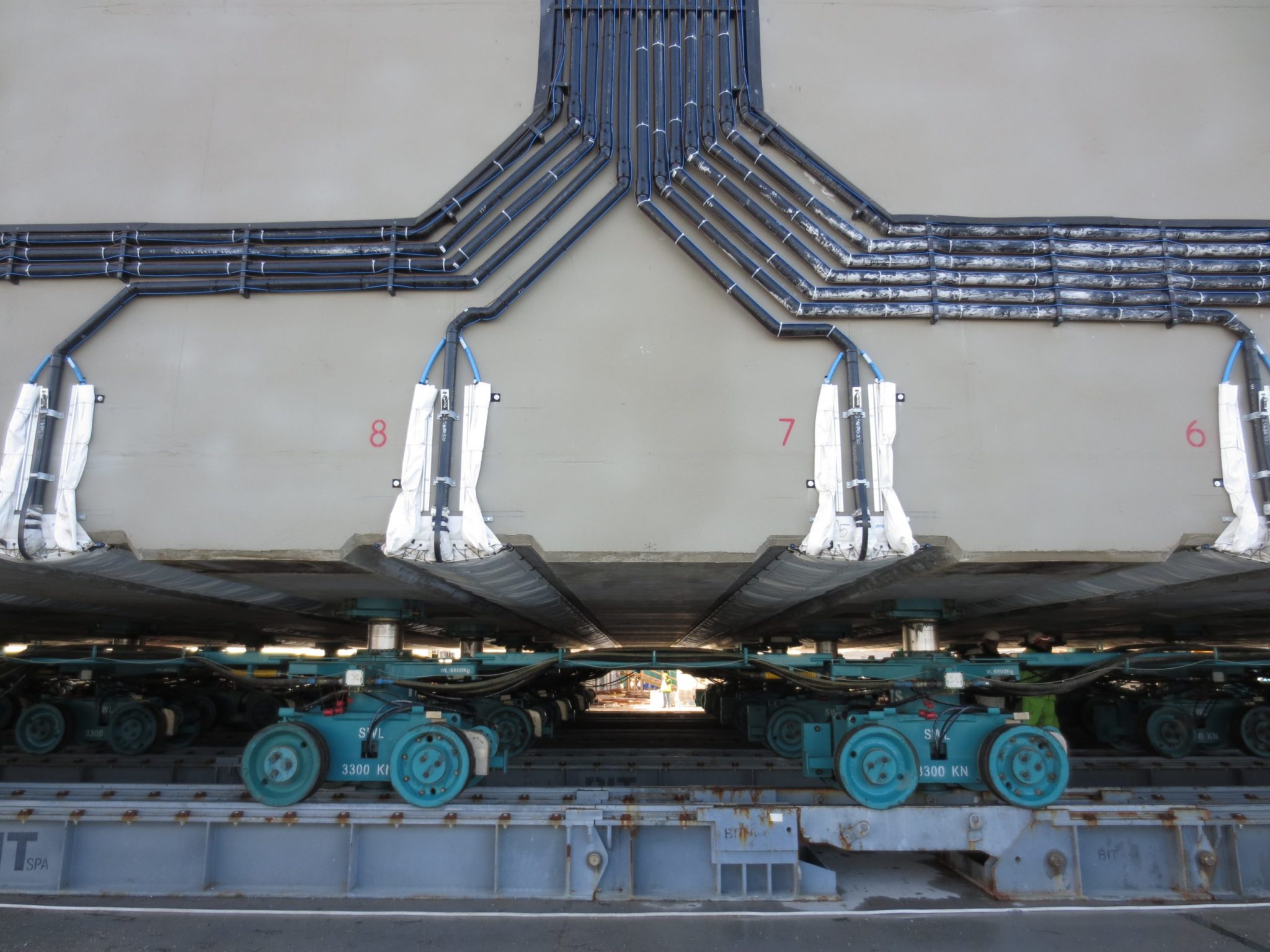

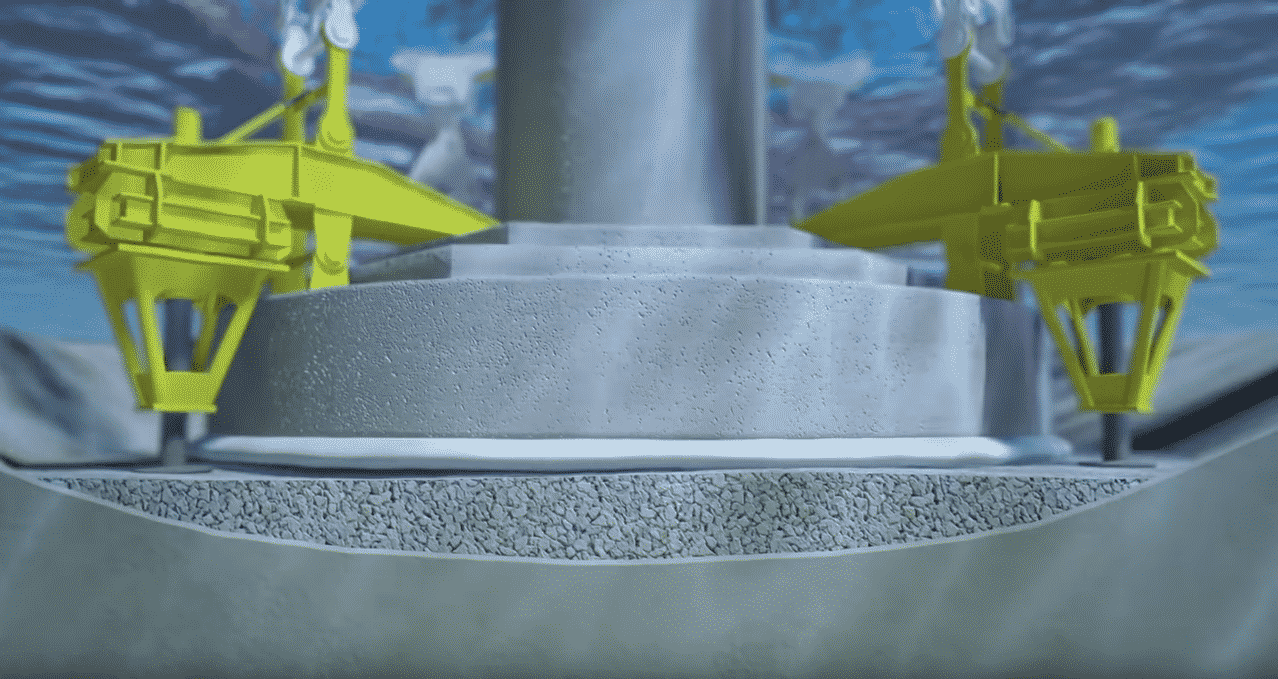

The 350m long berth is to accommodate Panamax type vessels with drafts up to 15.0 m and installed powers more than 70,000 kW. Concrete mattress has proved to be a more practical and cost-effective solution than the use of rock armour to protect the vulnerable sand bed.