TBM Launch & Reception Seals

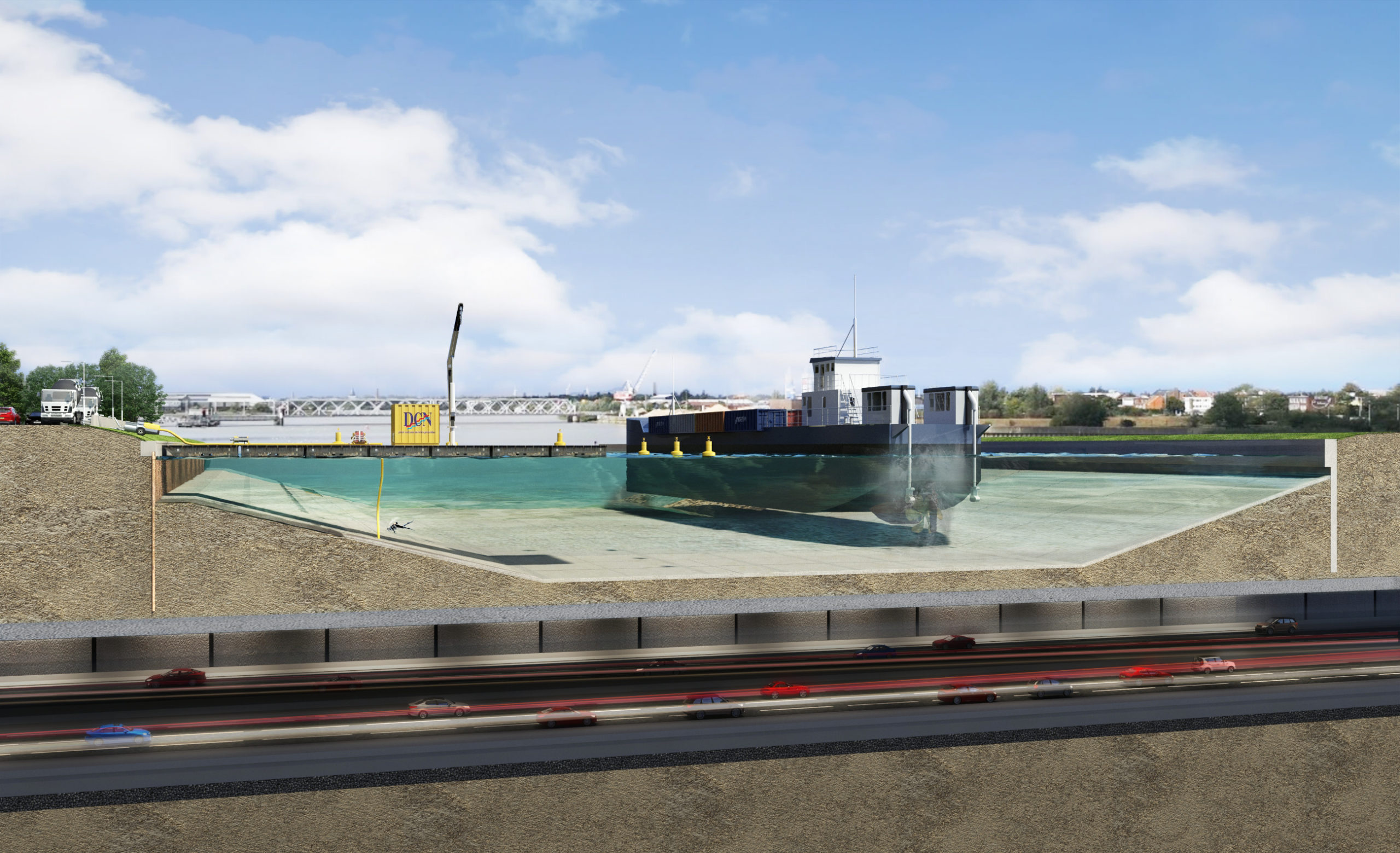

Bespoke sealing arrangements are needed for TBM launching and receptions, to manage:

- TBM pressure

- Lytag or grouting

- Groundwater control

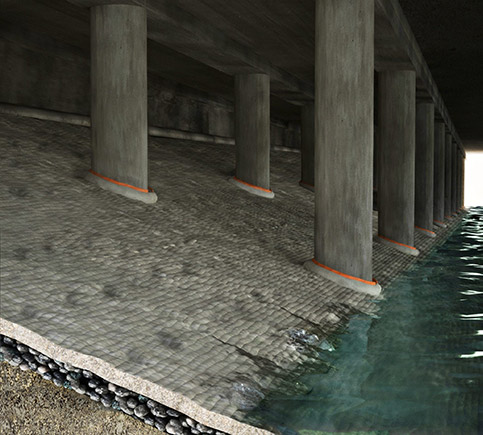

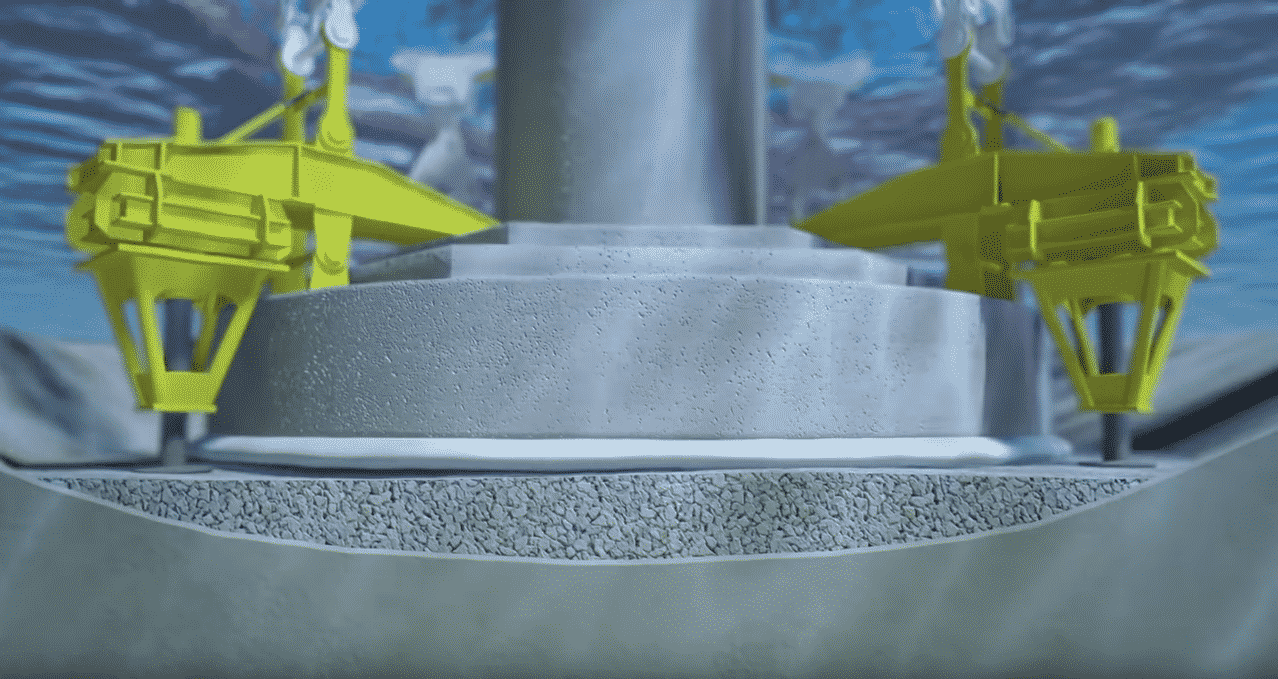

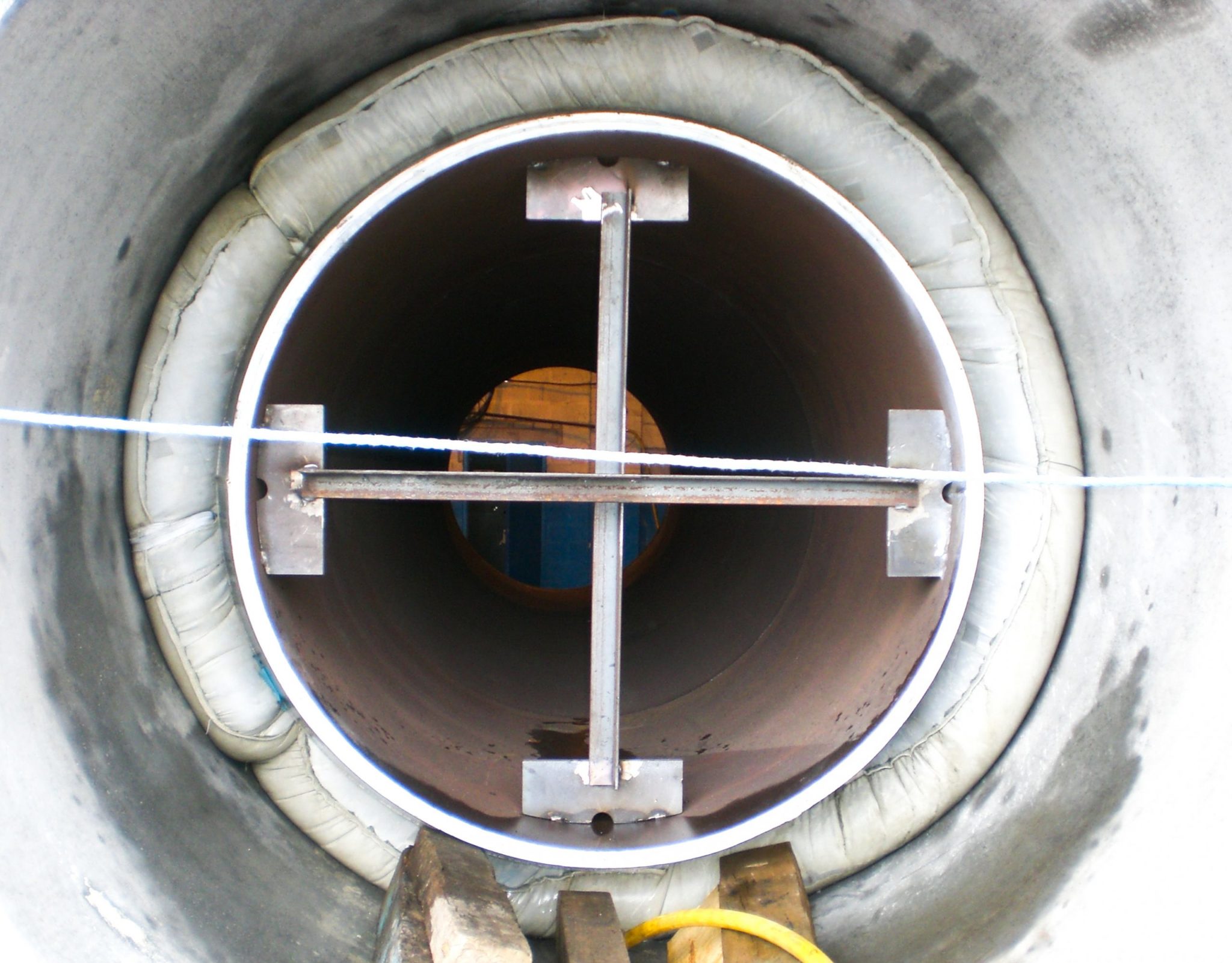

Solutions are required to seal and fill the annular void between the TBM or Tunnel Rings, and Launch/Exit chamber to manage risk, allow TBM pressurisation, and to form a stop-end to enable after-grouting of the tunnel annulus.

The narrow void to be sealed is difficult to access, and seal systems need to be robust and reliable for pre-fixing and remote filling without access. Sealing must be completed before the TBM is launched, making reliability critical to avoid delays.

Seals which make reliable full contact to completely fill the void are preferred to manage the risk of TBM face pressurisation and to limit water ingress or after-grouting leakage.

Grouted Seal Solution

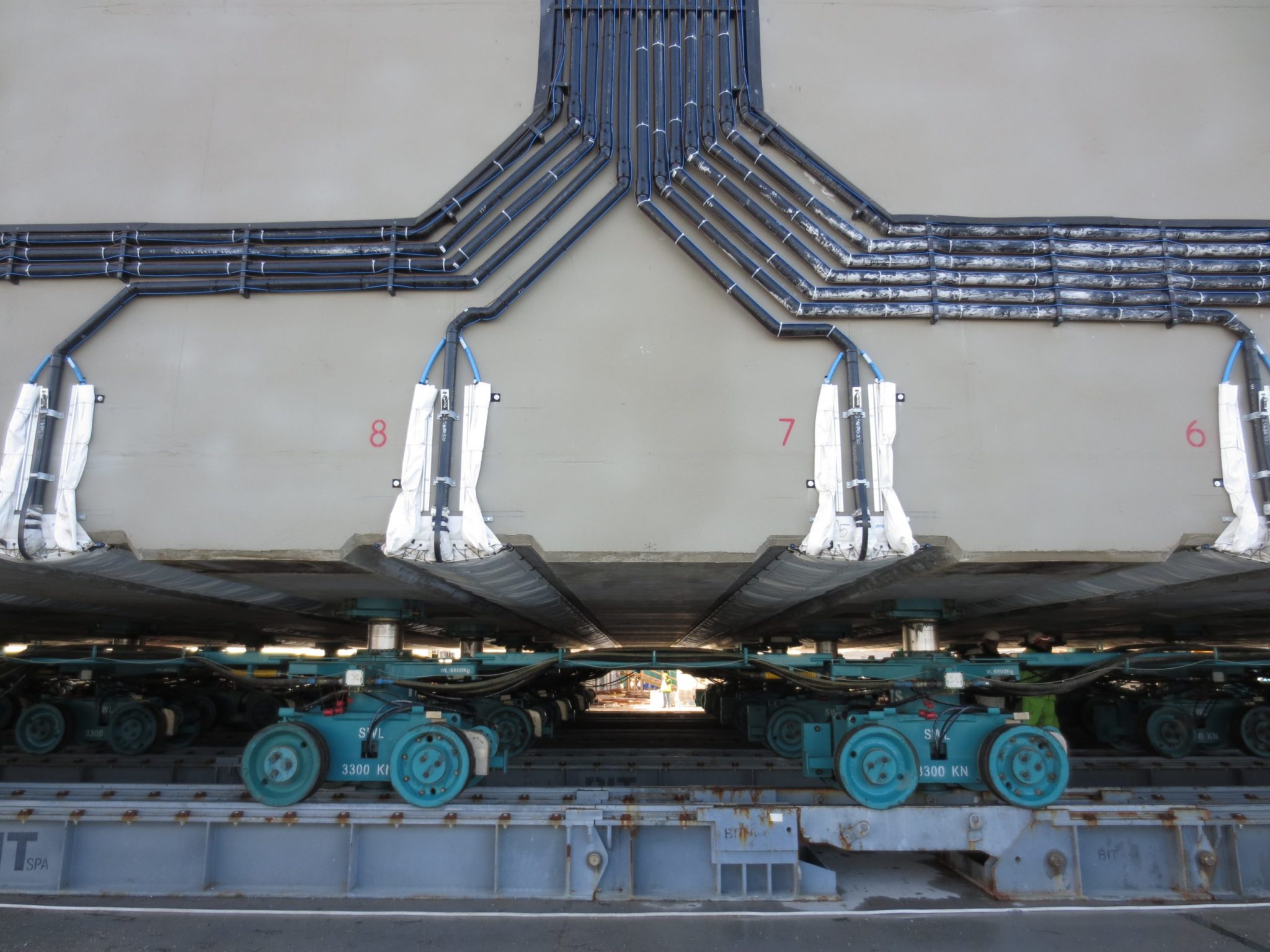

The fabric formwork seal is filled in situ with cement grout to form a grouted seal, reliably sealing the annulus between the launch chamber and the TBM shield or first tunnel ring. Ringseals are designed to withstand TBM face pressures, annulus grouting pressures and water pressures.

Installation

Each Ringseal is purpose engineered for each project.

Proserve engineers provide:

- Job specific General Arrangement drawings

- Risk Register

- Temporary Works calculations

- Installation Guidance

Proserve work with the Contractor to engineer the system suitably for their launch or reception needs.

Ringseals are fitted in a protective recess to avoid damage by the TBM as it passes. The Ringseal is often drilled and fixed to the SCL or can be pre-fitted in a steel seal can. Ringseals are often fitted some months before launch, before access is lost, and are usually provided with a fire-resistant rubber cover to provide protection on site between fitting and grouting.

Ringseals are manufactured in Proserve’s UK factory ensuring fabrication quality and control of lead time.

Along with the project specific drawings, documentation and installation guidance, Proserve provide flexible on-site engineer support, often for Ringseal fitting, and again for Ringseal grouting.

Benefits

APS-Proserve Ringseals provide an engineered one-stop grouted seal solution.

The Ringseal is manufactured as a complete continuous ring and does not rely on an overlap joint for performance.

Proserve provide detailed and project focussed installation guidance, on-going communication and support to the Contractor, and experienced engineer on-site support for the installation.