Concrete Seals

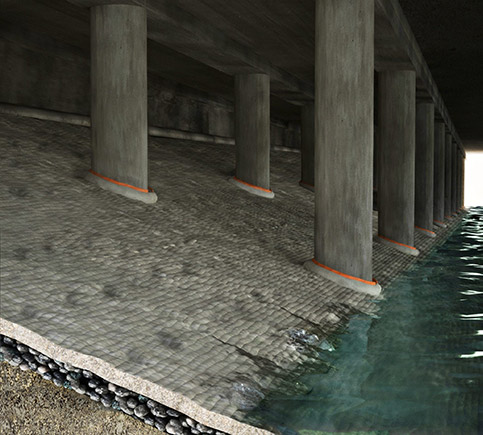

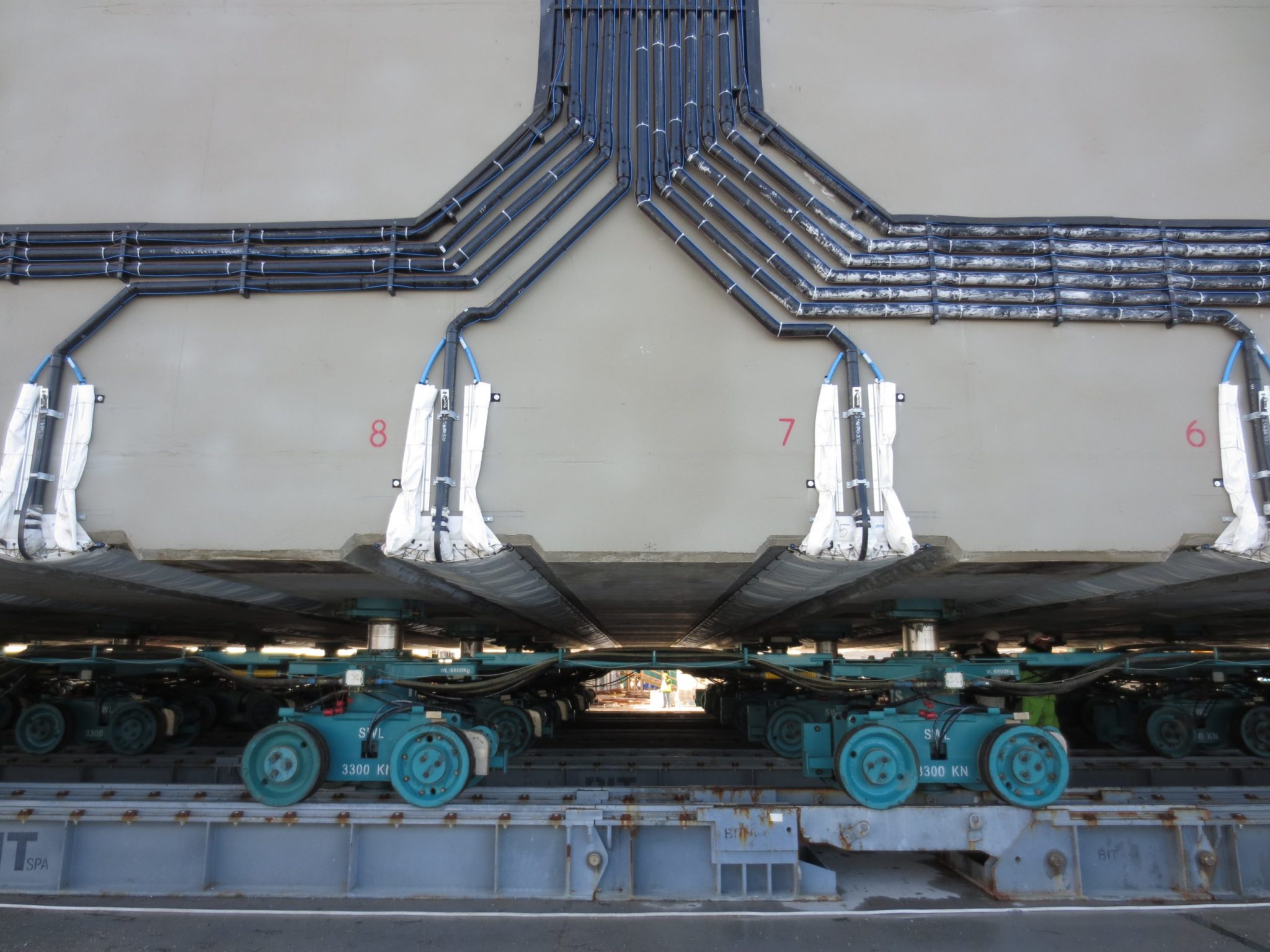

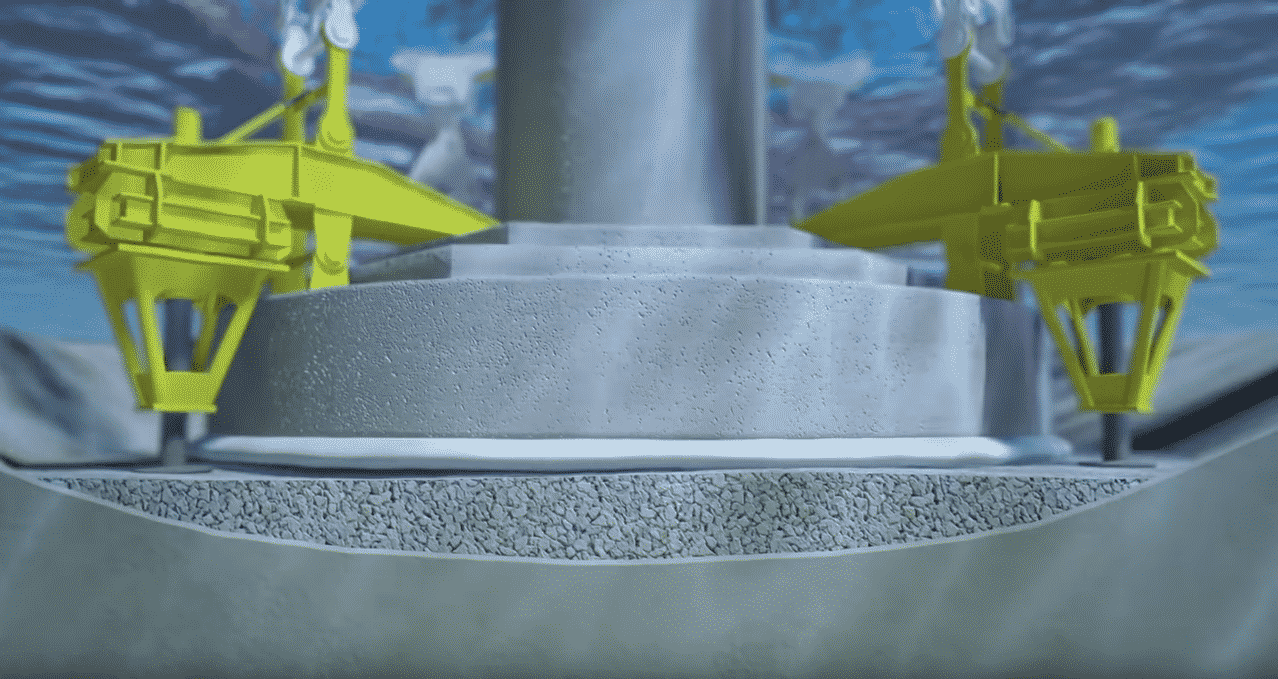

Unlike conventional formwork, fabric formwork is highly flexible, it can be condensed and fixed in place prior to the required filling time. Upon filling, the formwork develops from its condensed position to its filled position, taking up often large construction tolerances.

Condensed seals can be made to a range of lengths, curves, and shapes, including continuous rings. We first used condensed seals in the 1970s and have been developing them for more demanding conditions ever since.

Positioning

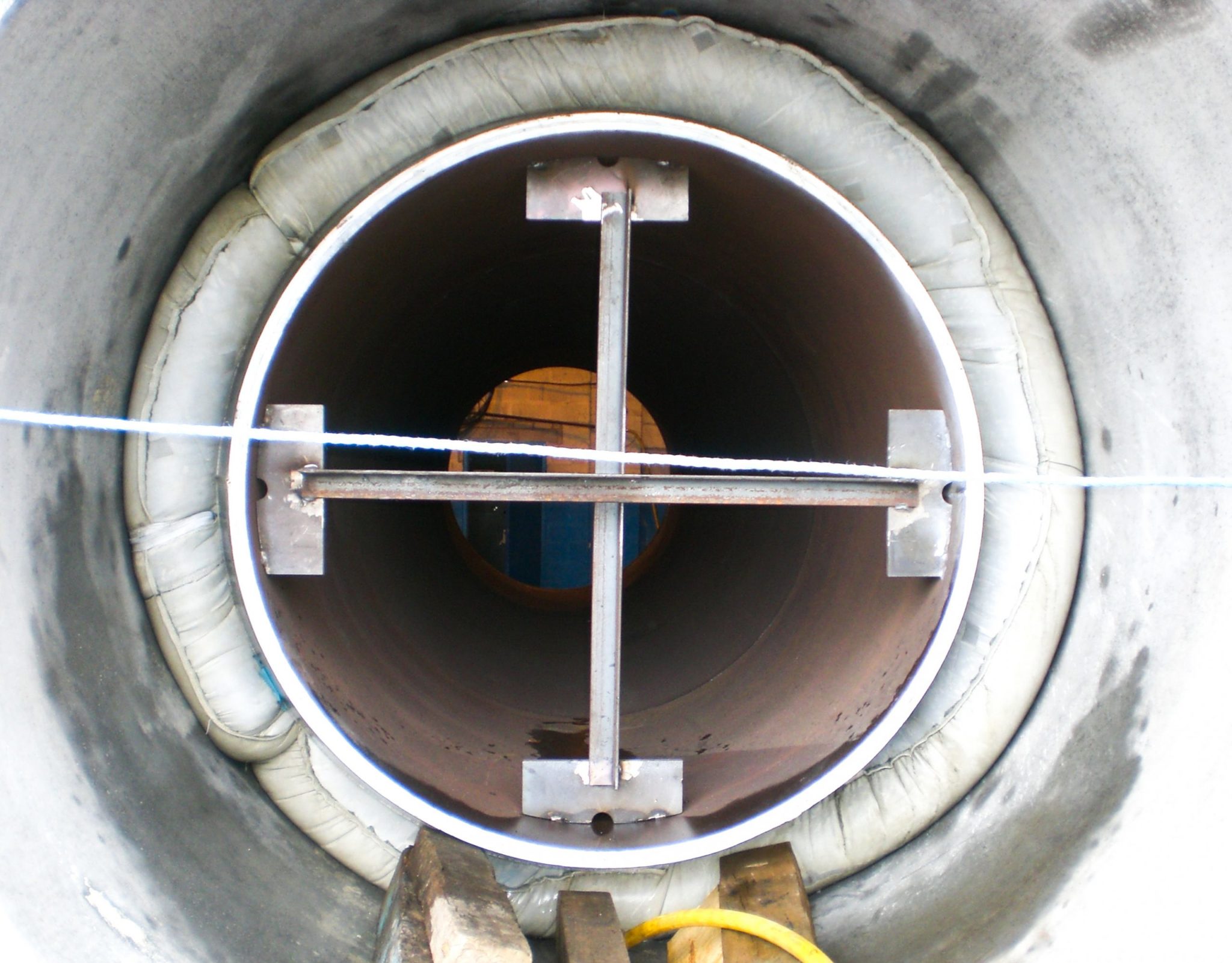

Condensed seals can be fixed to existing structures, in steel frames and lifted into position and prefixed into recesses for additional protection and for shear transmission if needed.

Filling

The fabric contained in the condensed arrangement can fill to 5 times its condensed width and 10 times its condensed depth. Internal diaphragms can be provided to control the position of the developing fabric during filling. A staged release of fabric during filling is also possible.

Applications

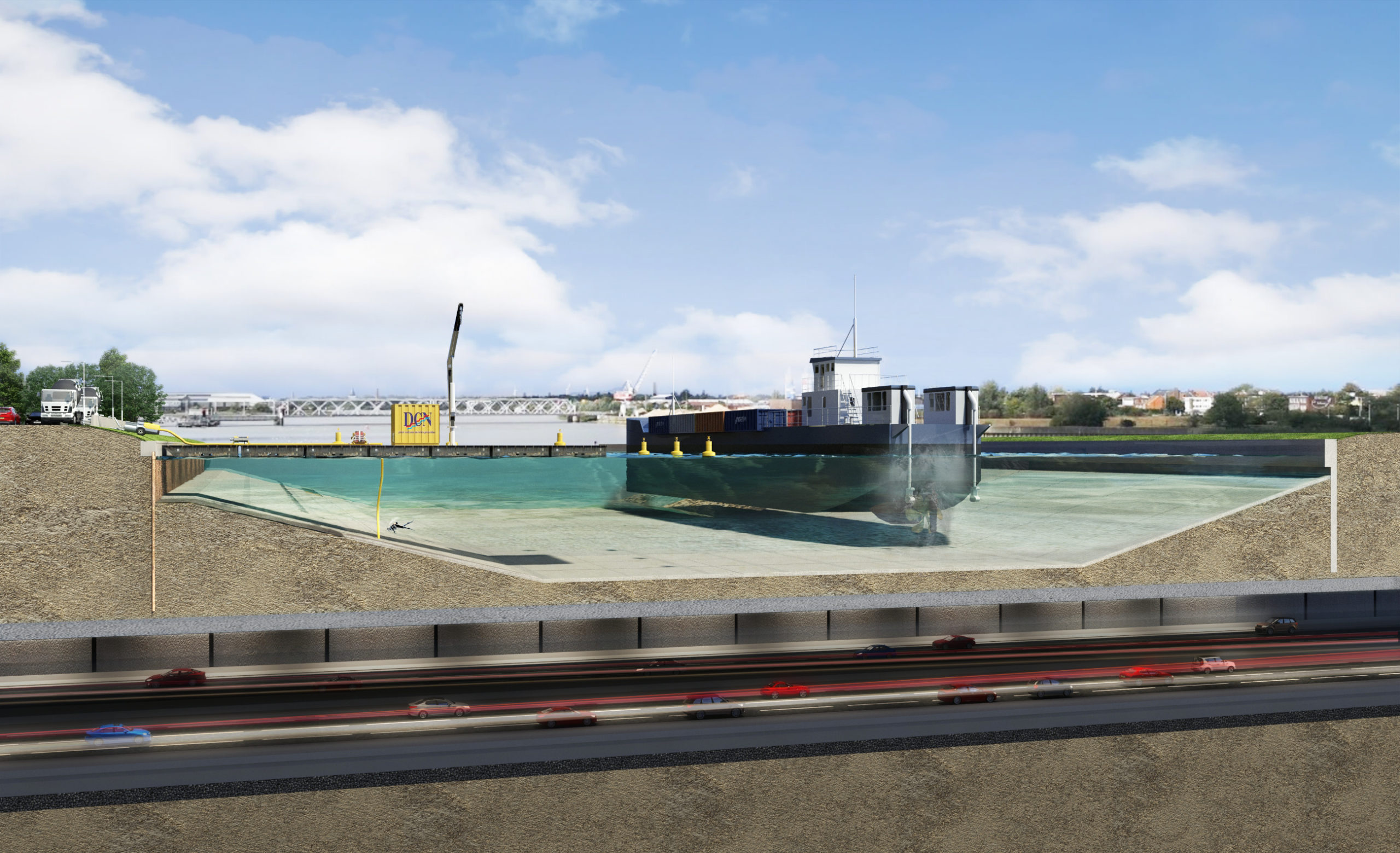

The above techniques and characteristics allow condensed grout bags to be used for a wide range of applications where access is constrained, and construction tolerances are to be taken up:

- Caisson bearings

- Caisson joints and seals

- TBM launch seals

- Pipe connection seals

- Marine pile connections

Condensed seals are usually delivered to site in their condensed configuration, having been condensed in our dedicated fabrication facility by experienced technicians.

All condensed seals will be provided as part of our wider service to ensure that the solution meets your project’s specific requirements and constraints. We complete a detailed risk management process to ensure that the construction sequence will result in a successful outcome. For condensed seals, this includes a detailed installation guide and filling plan, accompanied with our on-site engineer support and installation team training.