Precast Bridge Piers

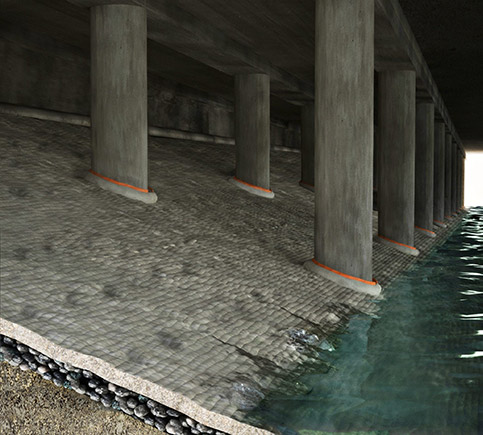

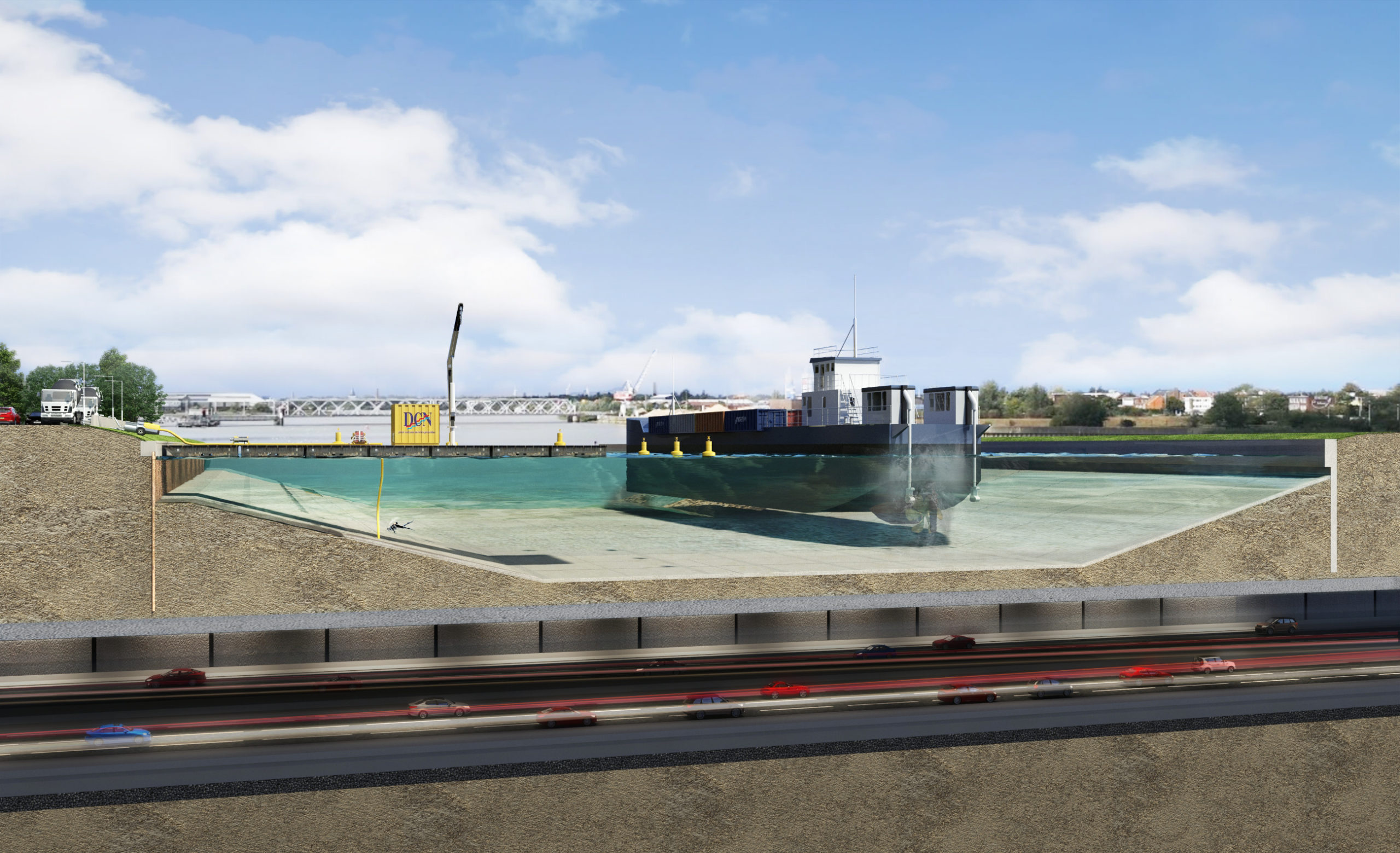

Caisson bridge piers are often used for sea bridge construction due to the speed of construction over water and the reduction of works required in the water. The bridge decks are often formed of precast or prefabricated elements which pose a restriction on the placement and final position tolerances of the pier units.

Stone bedding layers are often used as the foundation. This creates certain challenges when constructed underwater, such as:

- Difficult to level

- Liable to settlement

- Risk of washout and scour

All of these can make the required tolerances harder to achieve with potential delays while adjustments are made.

Compared to stone bedding layers, grout bag foundations are well suited to applications where:

- Construction tolerances are tight

- Settlement is undesirable

- There is a risk of stone washout or scour during or after construction

- When accurate stone levelling is not practical

- When working on a rock bed

- In seismic zones

Grouted Solutions

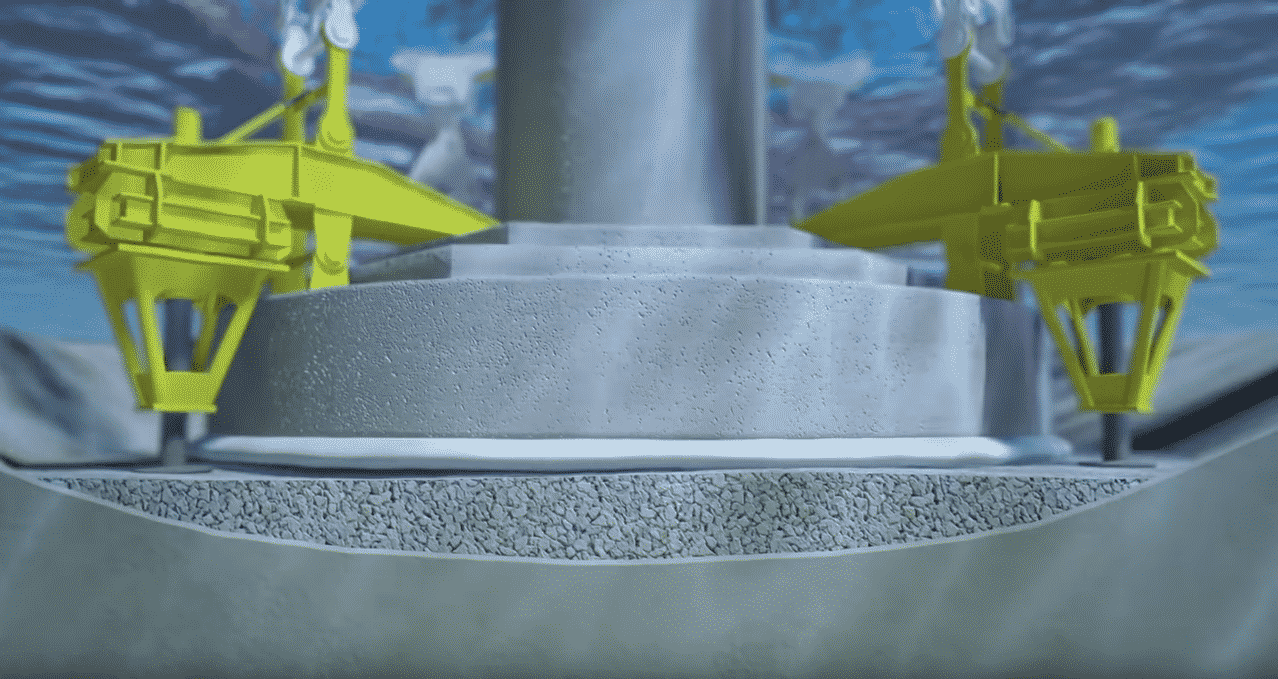

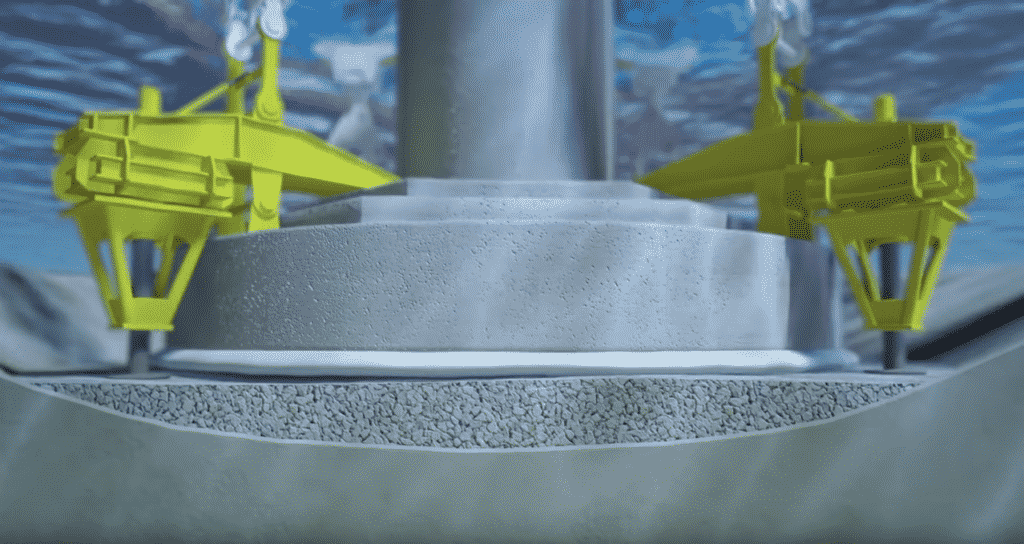

The grout bag system is an alternative to compacted stone bedding layers, providing a grouted layer which fills the void between the precast concrete element being placed and the seabed. Capable of managing a bed tolerance up to 900mm.

Installation

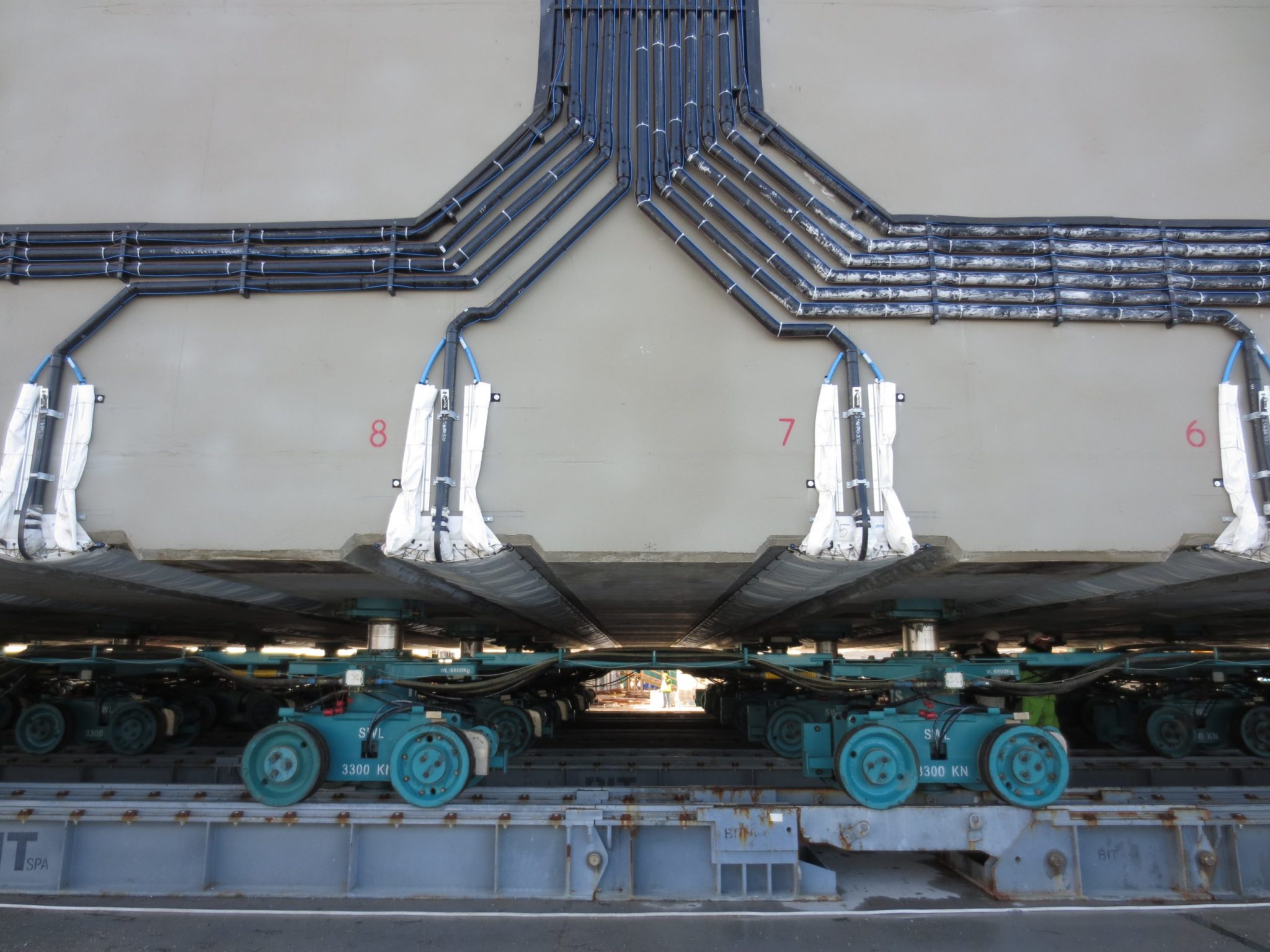

Foundation grout bags are specifically developed with the designer and contractor for each project’s particular requirements. Our engineers use a range of variables, not limited to:

- Bed tolerance

- Caisson level tolerance

- Initial stability requirements

- Shear transfer

- Uplift limits

- Transport distances

- Working environment

- Installation windows

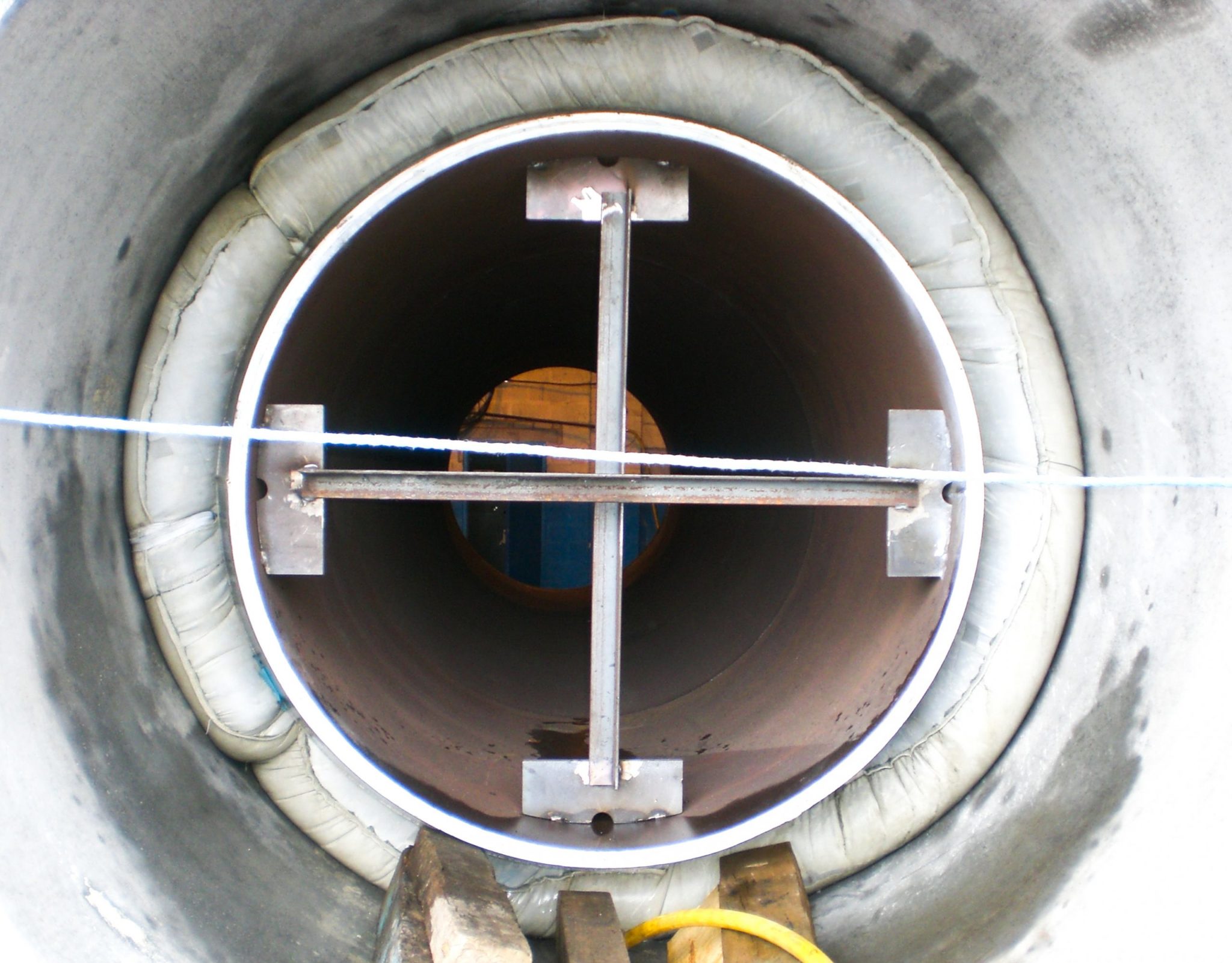

The grout bag and grouting pipes are prefixed to the concrete element in the casing yard, once the element is submerged and positioned on jacks, the bags are pump filled from a grouting barge. The grout bag controls the grout, filling the void between the element and the bed surface in a carefully designed sequence for guaranteed void filling and full contact with controlled uplift pressures.

Summary

Foundation grout bags provide control during construction by:

- Achieving tight construction tolerances and little settlement

- Absorbing large bed tolerances

- Eliminating the risk of washout

- Initial stability where required,

- Even distribution over the caisson base

- Eliminating requirement for stone layers when working on rock

Performance has been demonstrated by 30 years of proven performance on some of the world’s largest marine construction projects.