Research and Development is essential to allow us to support our clients in meeting tougher construction challenges in ever more sustainable and reliable ways.

We focus on 4 areas of R&D:

- Advancing industry knowledge

- Fabric formwork advancements

- New applications

- Working methods

Advancing industry knowledge

We aim to answer the big questions at the cutting edge of scour protection systems:

- How can scour protection be effectively designed for advancements in vessel propulsion systems?

- How can scour protection be made more durable?

- How can we decrease cost, time and resources required in construction of high-performance scour protection systems?

We use experience from the performance of existing scour protection systems the world over, industry guidance, collaboration with industry experts, scale model testing and CFD modelling to test new hypotheses and we regularly publish our findings for the wider industry to use.

We open our facilities once a year so that we can impart this knowledge to construction professionals aiming to benefit from the latest advancements in their projects.

Fabric formwork advancements

The versatile nature of fabric formwork means that we are constantly exploring and consolidating new methods of using fabric formwork to solve different construction challenges.

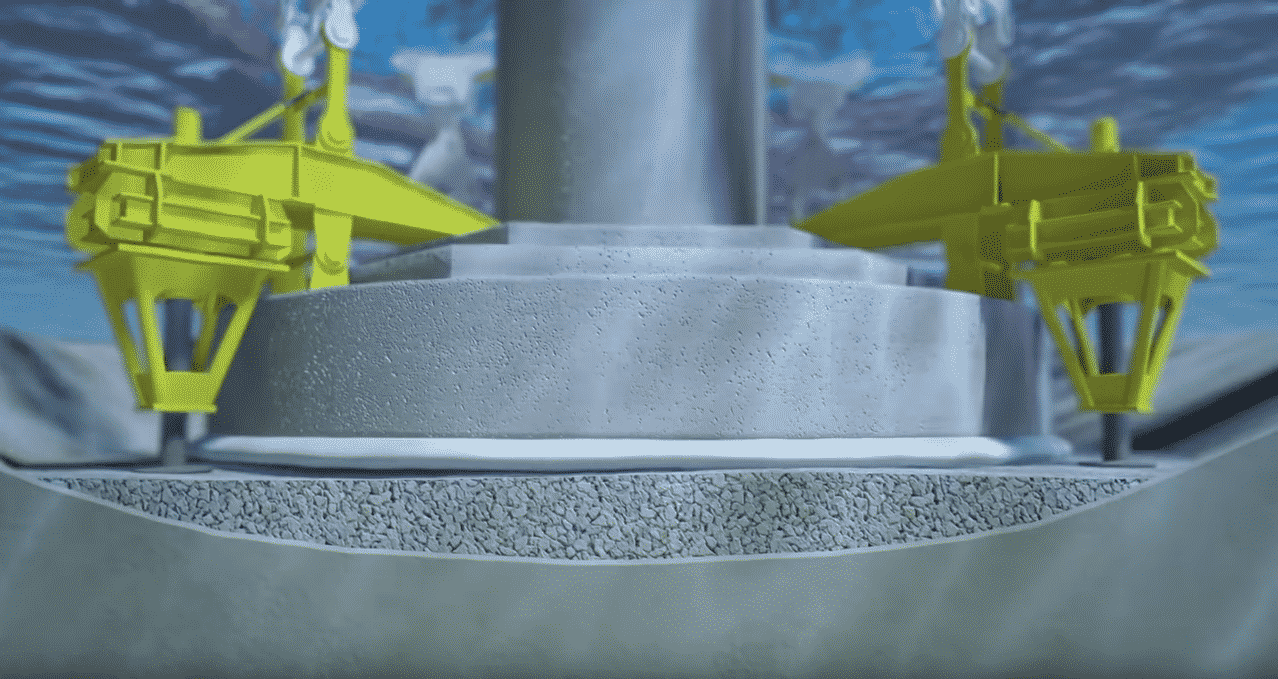

In contrast to conventional formwork, fabric formwork can expand and change shape during filling, this allows us to engineer applications where the fabric must be condensed or protected, to later deploy and create high quality concrete in a different or larger location.

Advances in fabrics and combination of different fabrics allow a high degree of control of the fabric during filling, ensuring the required geometry is achieved, which allowing for generous construction tolerances. We use:

- Single layer fabrics, synthetic and natural fibres

- Twin layer fabric

- PVC coated fabric

- Mesh and netting

- Webbing

We are constantly developing new methods of combining these fabrics to suit new applications and yield high quality concrete construction with improved sustainability.

New applications

Together with our clients we develop new applications to overcome construction challenges.

These collaborations often start with a contractor identifying that plain concrete can provide a durable solution, we then work together to assess the engineering requirements of the solution and develop a reliable method of forming the required concrete.

Some examples of recent developments include:

- Wave wall scour protection using CT Bulk Mattress

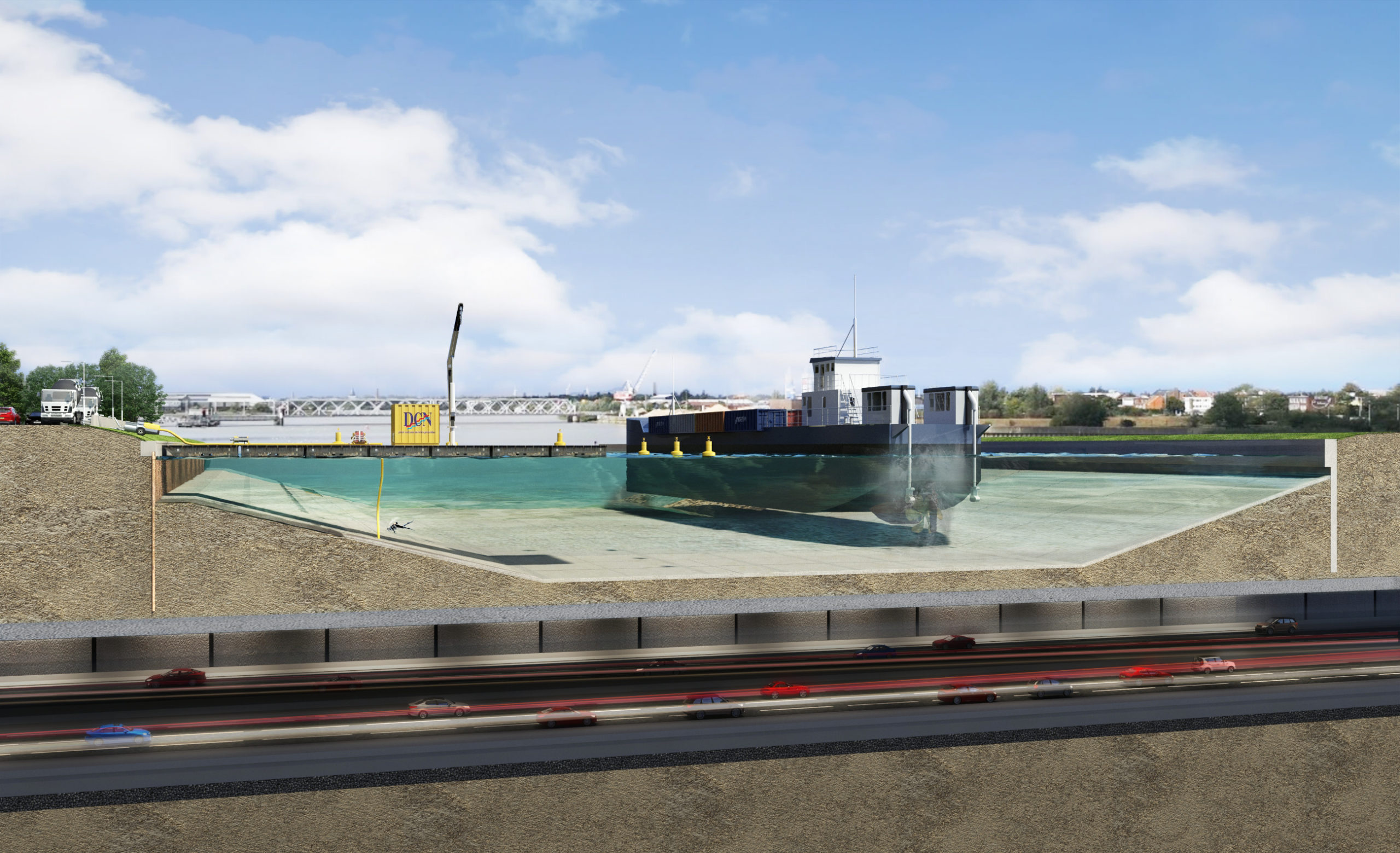

- Thick slabs to prevent sinkholes and marine contamination in nearshore tunnelling (C Bay)

- Insitu concrete blocks (La cotte – Jersey)

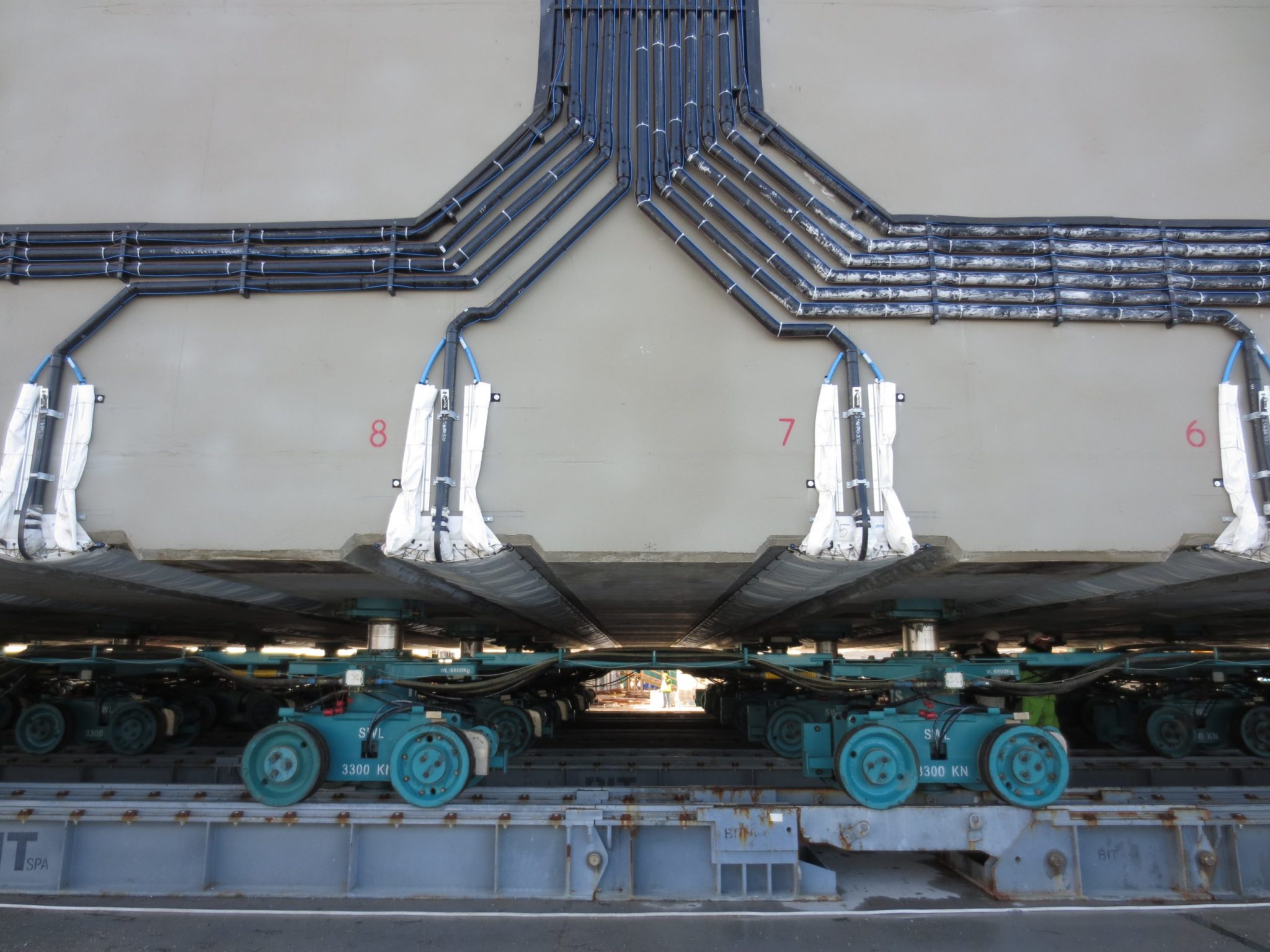

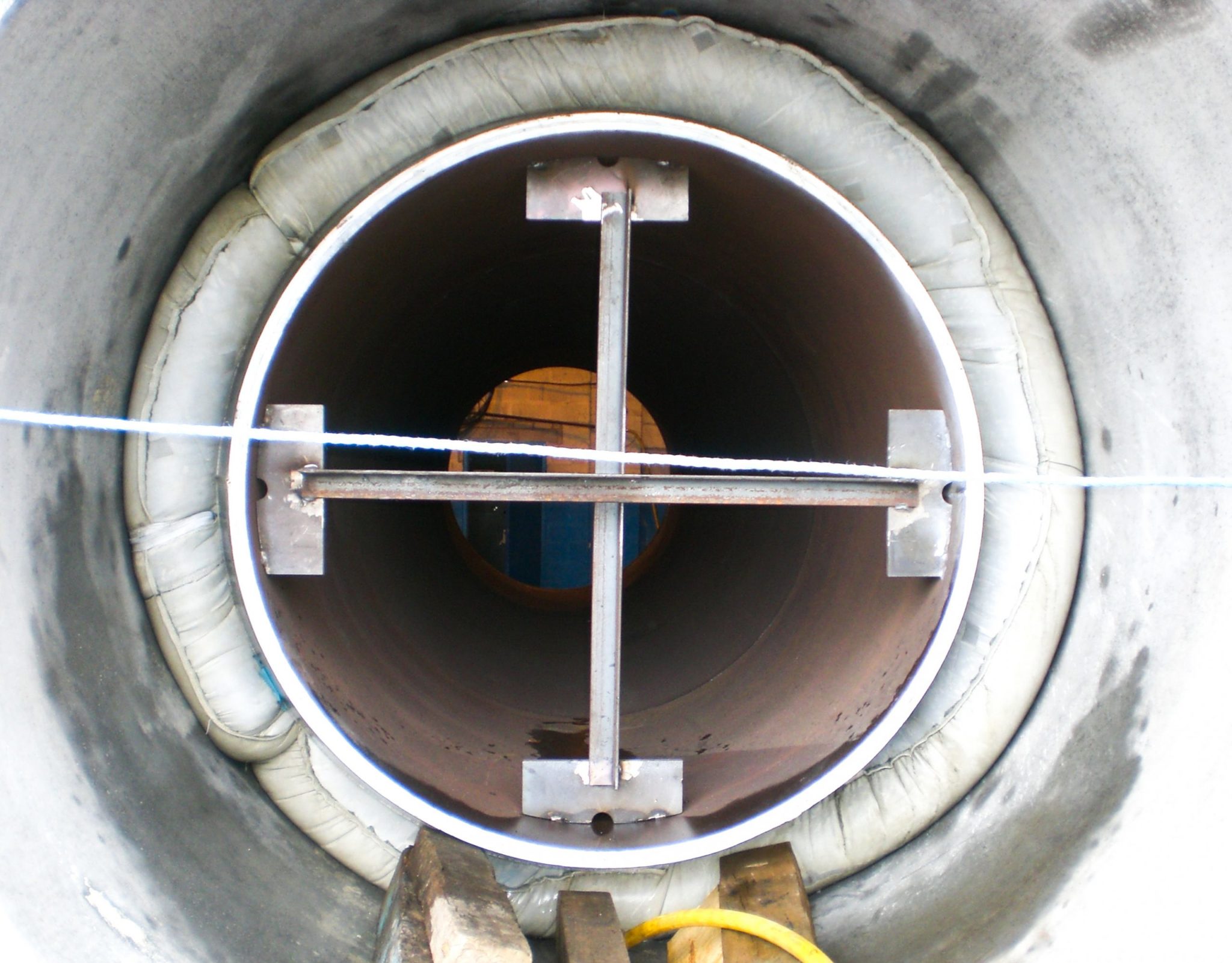

- TBM launch Ringseals

- Open hole mattress for revetments in high wave action

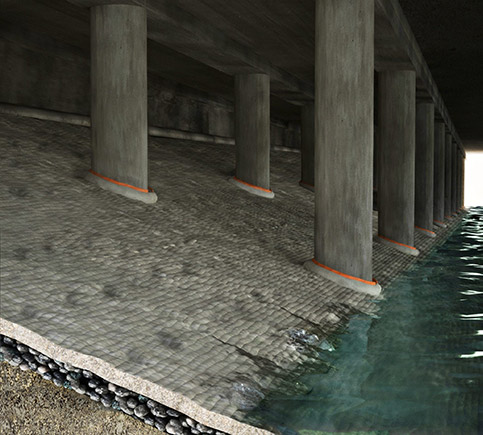

- Integral seals around piled jetty piles to prevent loss of fines

- Grout sensors

Together we can create solutions to control underwater concrete construction.

Working methods

We use latest construction and survey methods to increase reliability of construction. We use our experience of working extensively across marine civil engineering, from tunnelling to underpinning, from sea crossings to ports, applying appropriate techniques and technology when the opportunity arises.