Caisson Settlement

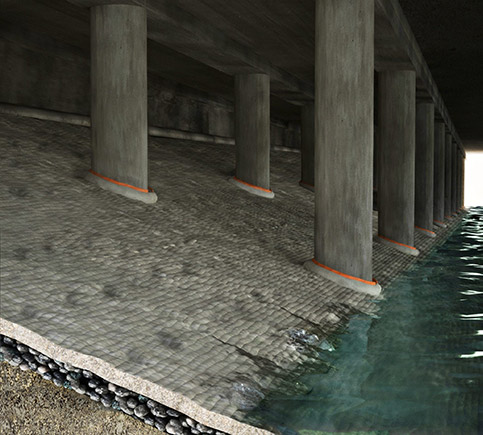

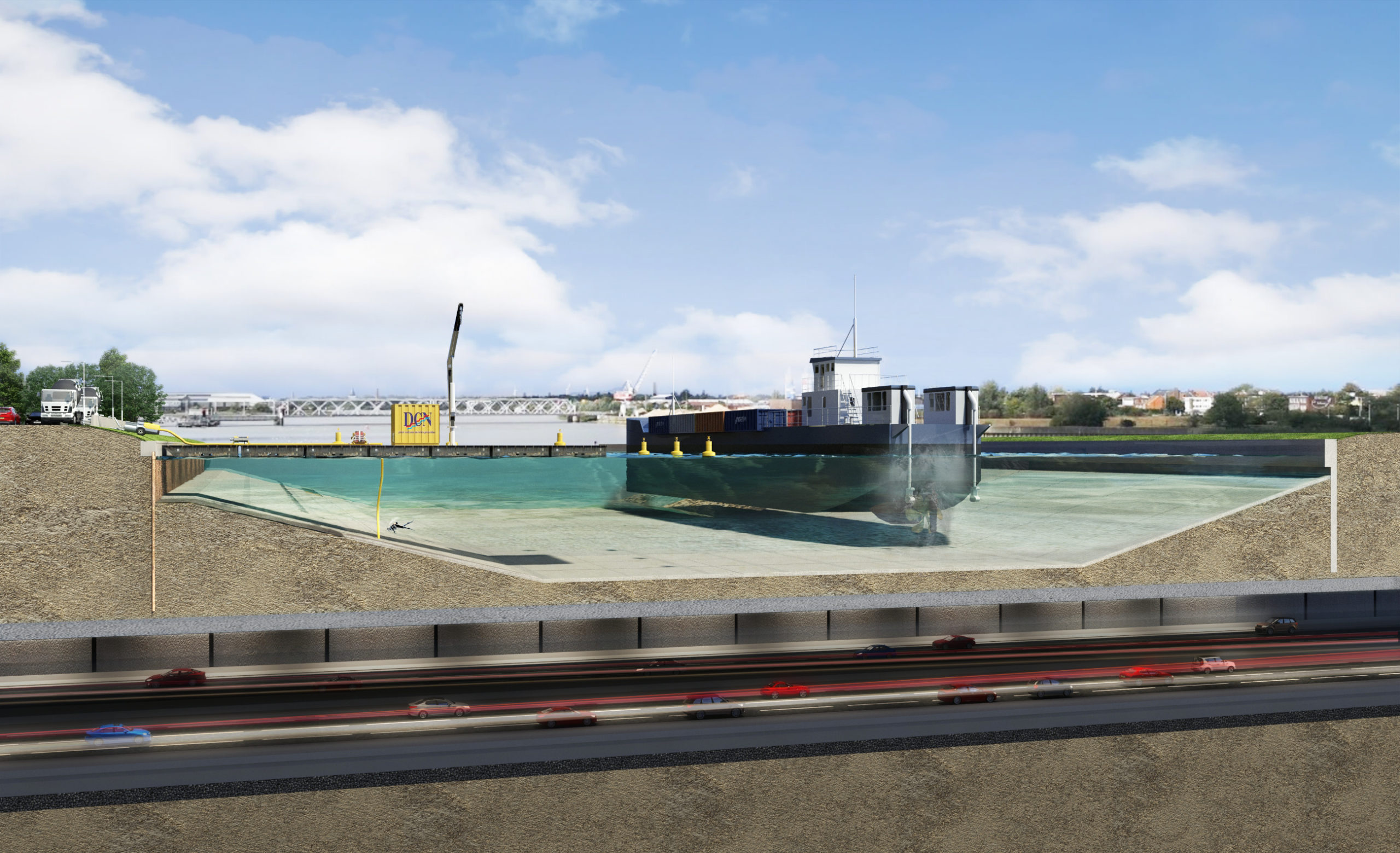

When placing caissons and other precast marine structures, there is often a need for permanent or temporary bearings to specific areas with very low settlement. The bearings can be required in limited access areas and must be achieved first time as remedial works are impractical.

Marine construction tolerances can be large (± 100mm or larger) meaning that unconfined grouting to achieve a bearing is harder to control and at higher risk of washout, loss or achieving a partial bearing.

Grouted Bearing

When compared to bearings formed using elastomeric, aggregates, solid materials or unconfined grouting, grout bag bearings have a number of advantages, including complete contact between the elements regardless of:

- Slope

- Undulations

- Wide construction tolerances

- Current conditions

All grout or micro-concrete is fully contained within the bearing, eliminating potential contamination of other areas and the risk of washout of the bearing before it sets.

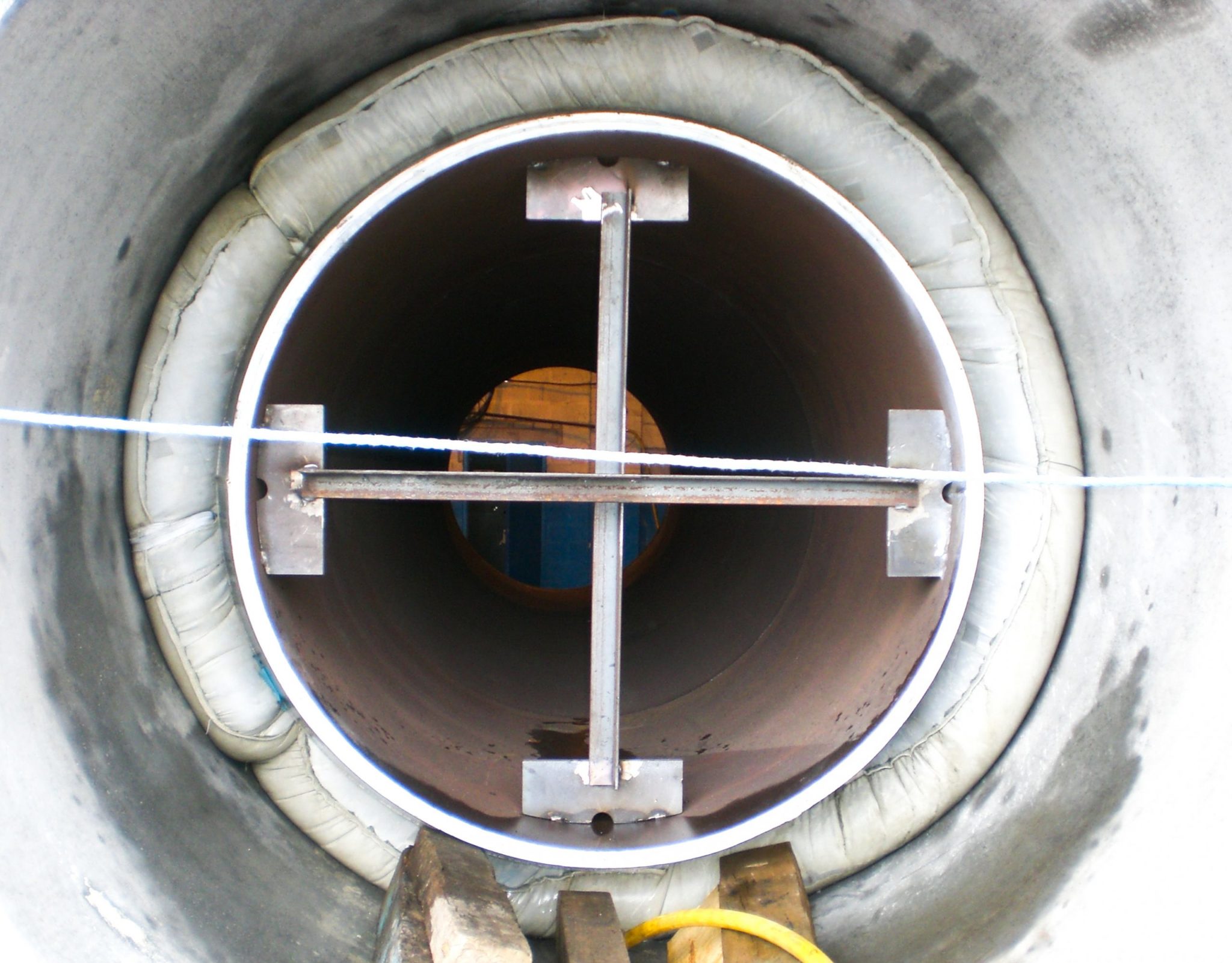

Installation

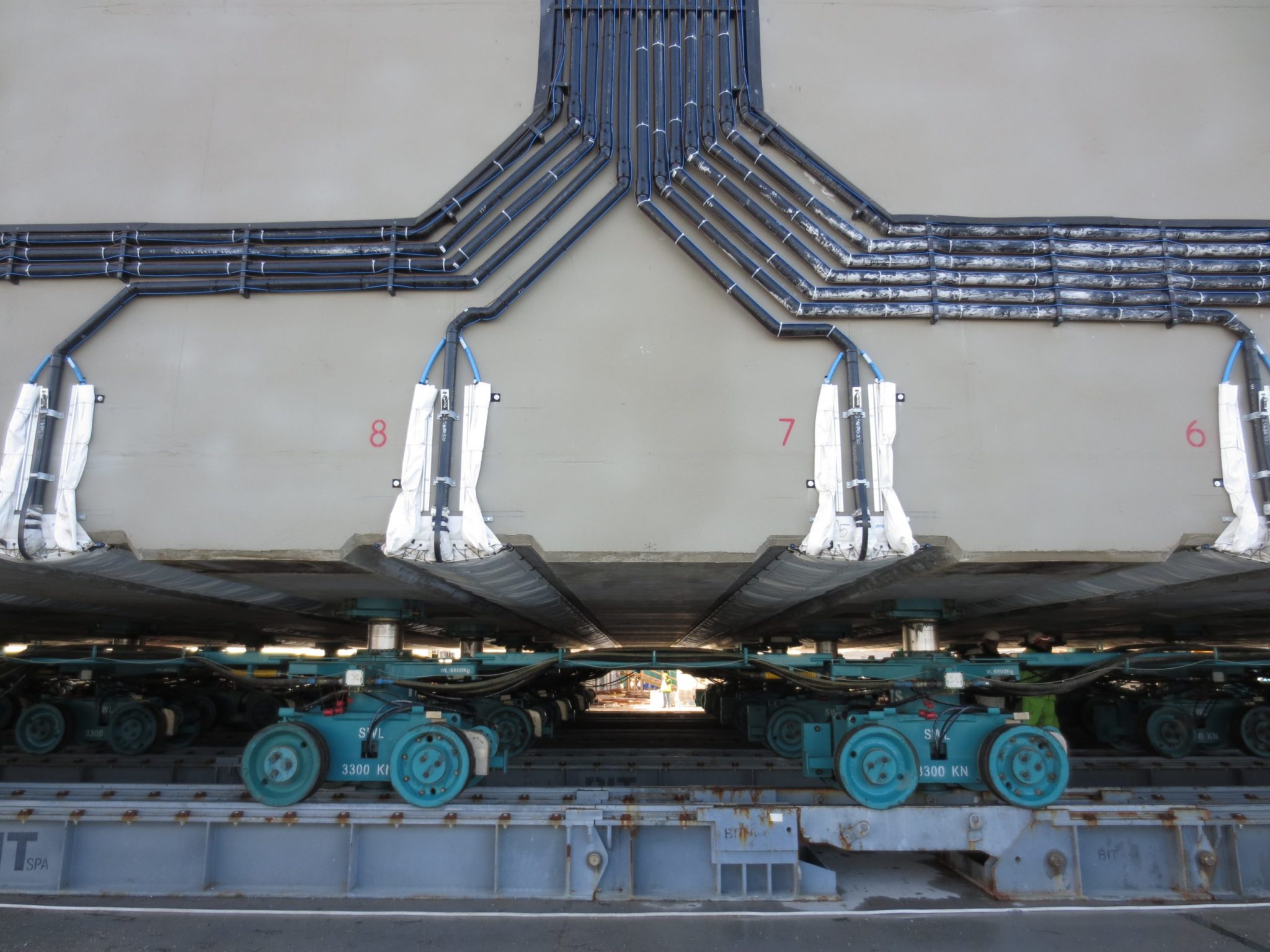

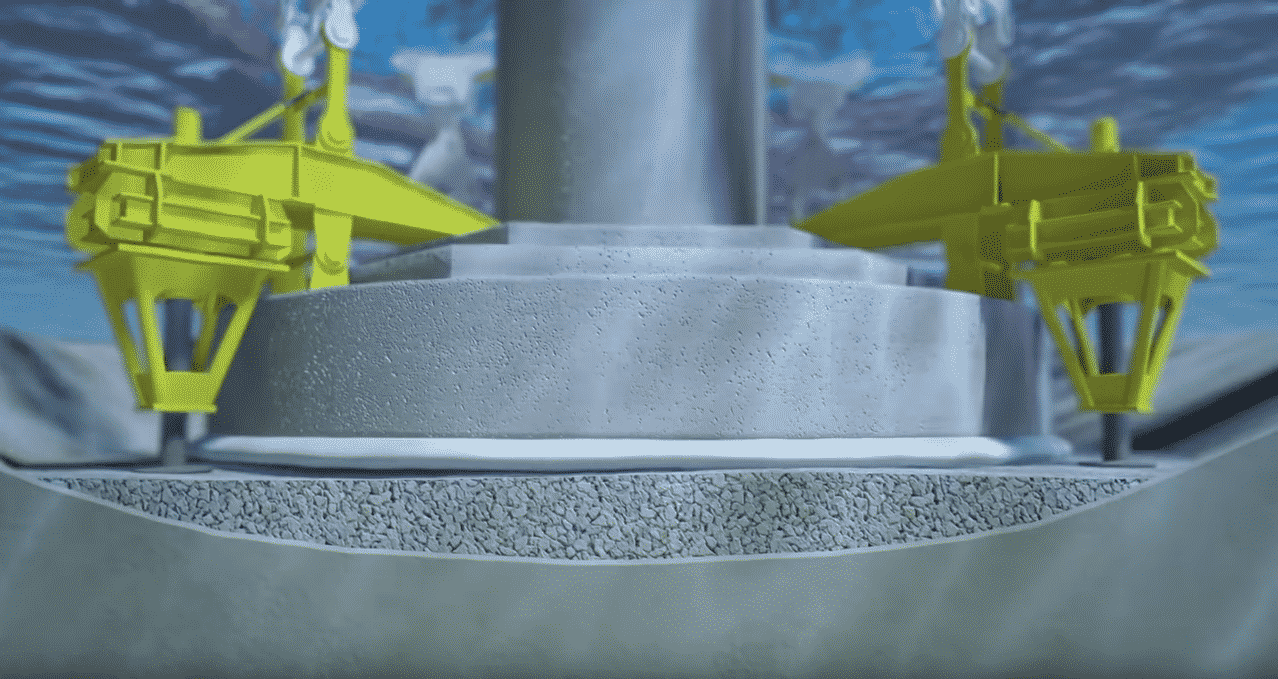

Grout bag bearings come in two different forms, those fixed to the element, a top down bearing and those positioned on the bed or pile cap in a steel frame, bottom up. They can also be at any other orientation, including vertical when appropriately restrained.

The grout bag used to create the bearing is fixed into position and pump filled in situ in tremie fashion.

Filling is continued until a back pressure of 10-20 kPa is achieved, guaranteeing a complete contact bearing, driving air and water out of the void.

Advantages

- Creates a bearing to suit the void to be filled with no trapped air or water voids

- Confines grout to only where it is needed

- Can be tailored to suit any void and tolerance

- Proven reliability with over 30 years of use with zero failures from over 3,000 bearings.

- Shear keys can be easily incorporated on both faces if required in design.