Our Expertise

To support our clients in overcoming their construction challenges we create solutions that go beyond providing fabric formwork.

We work with our clients to fully understand the requirements of the concrete they are to achieve and their working constraints. We apply our experience in marine construction and our unique expertise of forming concrete in the marine environment using fabric formwork to develop concept solutions and construction methods that allow our clients to create the required concrete practically and reliably.

Collaboration

We develop our concept solutions closely with designers and contractors to have a positive impact on other elements of construction, such as removing construction processes, decreasing complexity, and allowing greater tolerances for the construction that remains. The earlier we are involved in a project the greater our impact can be.

Reliable and Robust

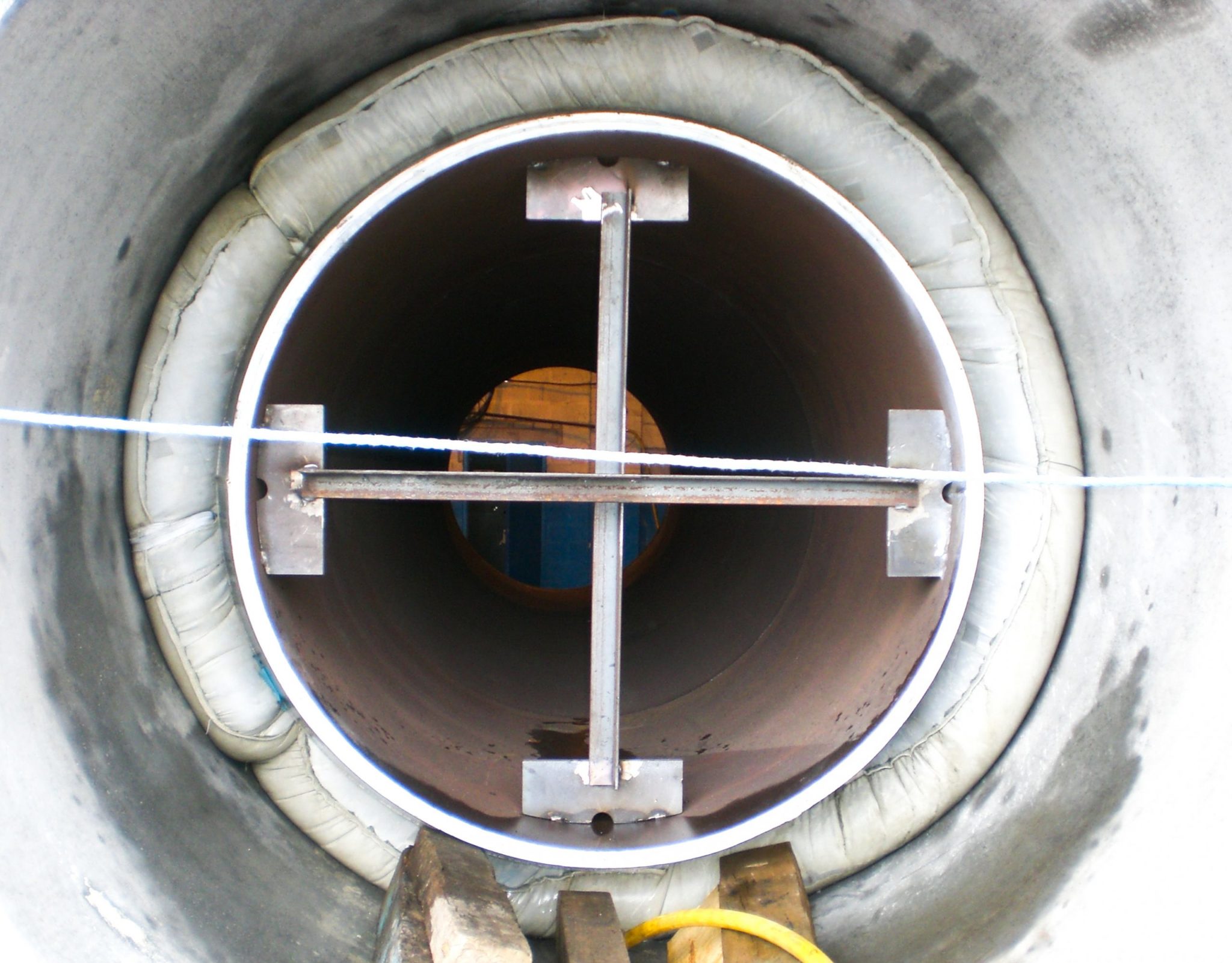

Concepts developed in this manner can often be creative or innovative requiring careful development of the detail and risk management through our construction engineering process to bring these concepts through to successful construction. This can include creating scale or full-size trials to test new fabric formwork arrangements and innovations and how all elements perform in combination.

We create concept solutions for small but challenging projects, through to some of the world’s largest marine construction projects providing control and reliability of construction outcome.

Experience

Our concept solutions are frequently taken through to successful construction, such as:

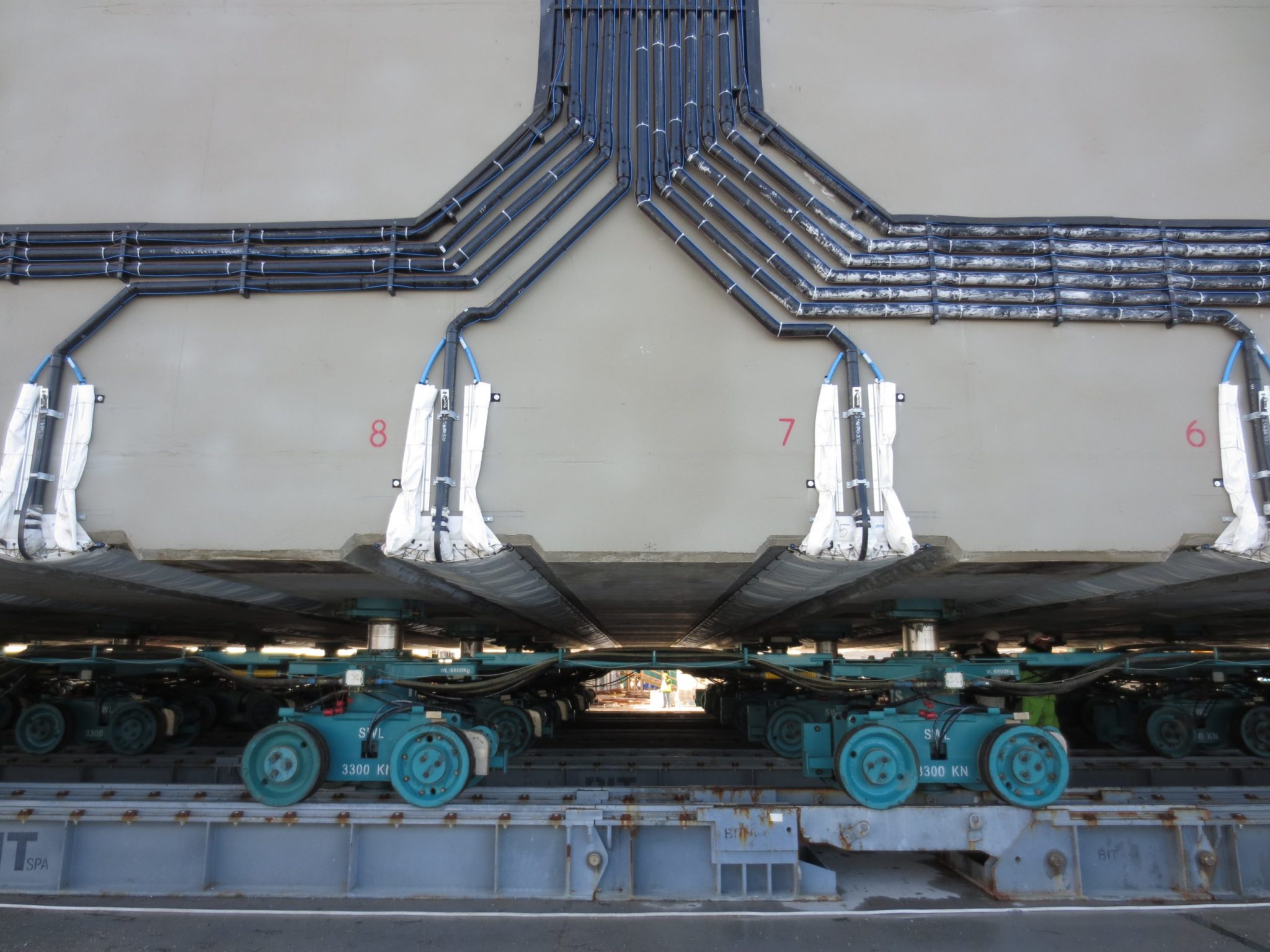

Venice barrage foundation grout bags

- Designed to resist 15km of towing on the bottom of the caisson and to develop to 2.8m wide from a 0.7m wide recess providing finished 5mm level tolerance once grouted from a bed tolerance of ±300mm.

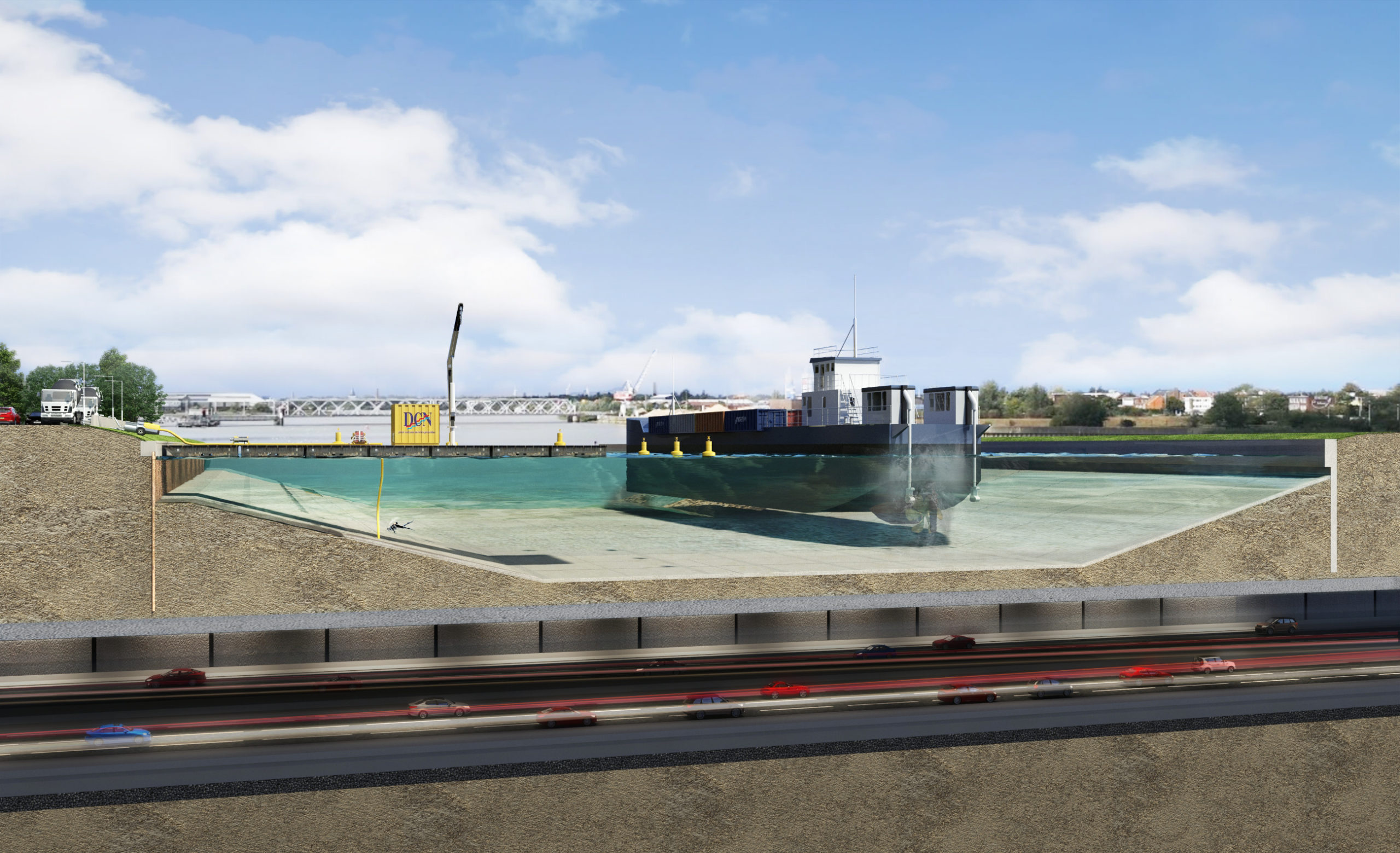

La Reunion bridge pier foundation grout bags

- Full base concrete foundation formation without diver presence

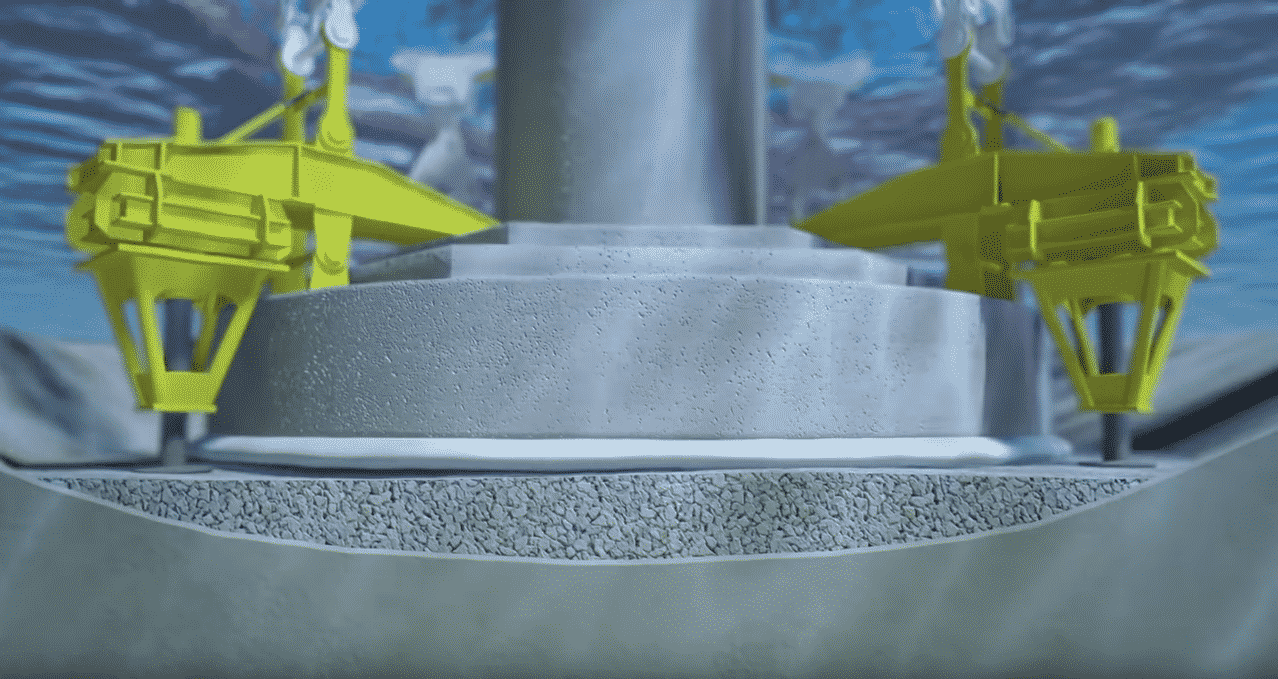

Olmstead Dam caisson seals and bearings

- Condensed formwork to resist 2m/s river flows and avoid fabric trapping on placement, taking up tolerance between caissons when filling providing initial bearings and seals for after grouting

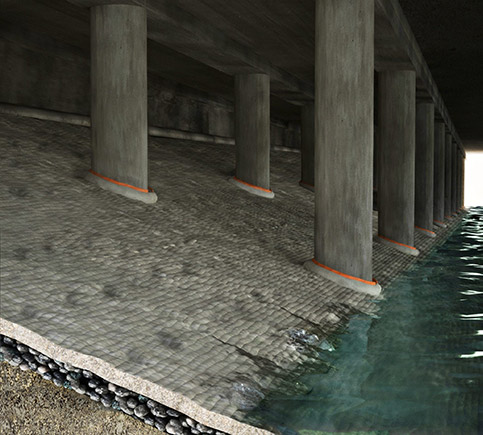

Pittenweem wave wall

- Underscour protection mattress, 1.2m thick to resist wave impact loading, uplift and to prevent washout of the bedding stone.

Rothera wharf, Antarctica quay wall grout bag bearings

- A combination of rigid and fabric formwork to create bearings on an uneven rock slope following placement of the initial structure.

All these projects required the development of a new approach in the use of fabric formworks in construction to ensure reliability of outcome. In every case we developed methods to demonstrate that the proposed construction would be carried out successfully before construction started, validating our concept solution in the process.

If plain concrete can solve a problem, but you are unsure how to make the construction a success, please get in touch, we would be delighted to increase our capabilities together.