Scour Protection

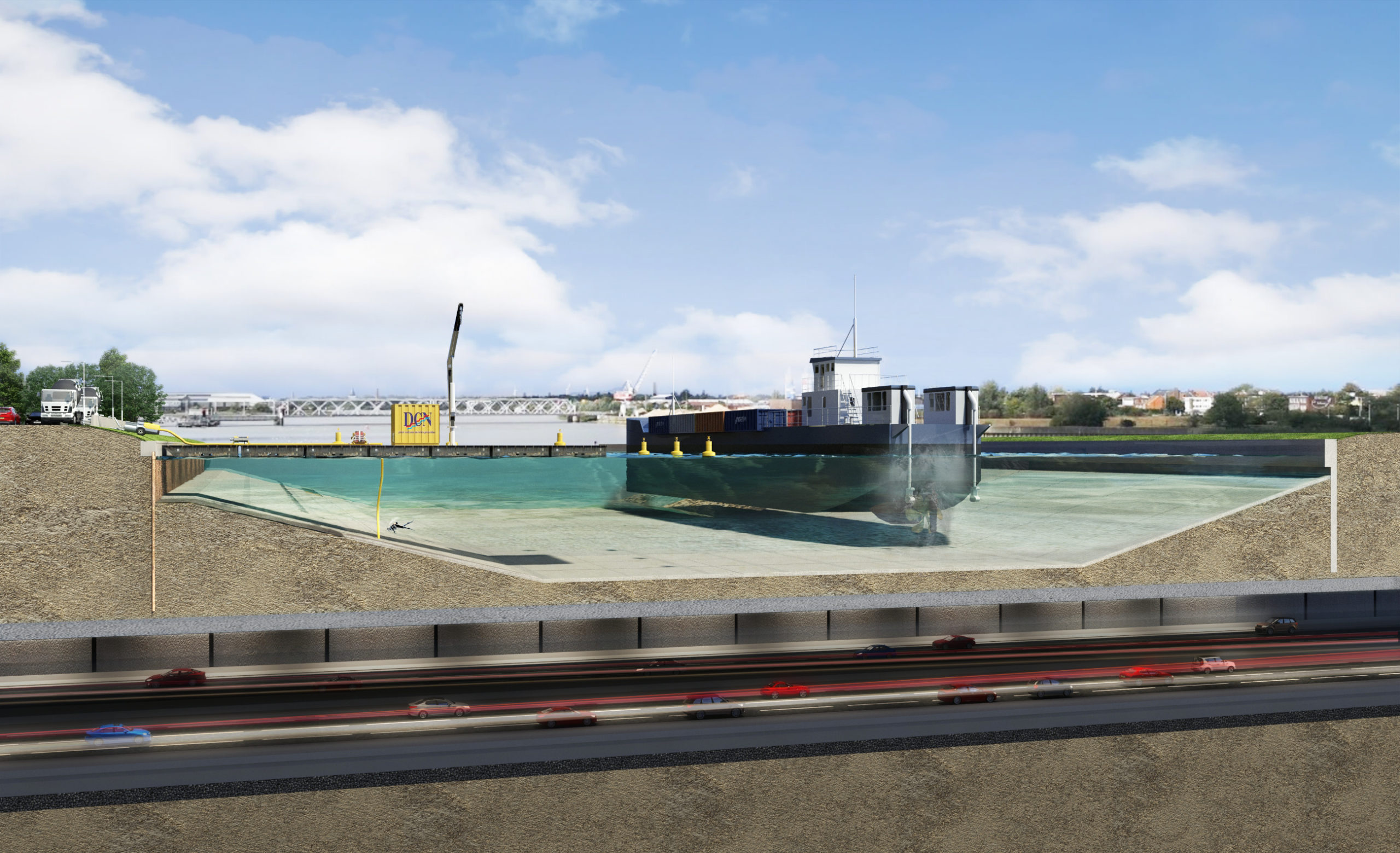

Piled revetments can suffer erosion from both vessel propulsion and wave action which can comprise the stability of the revetment.

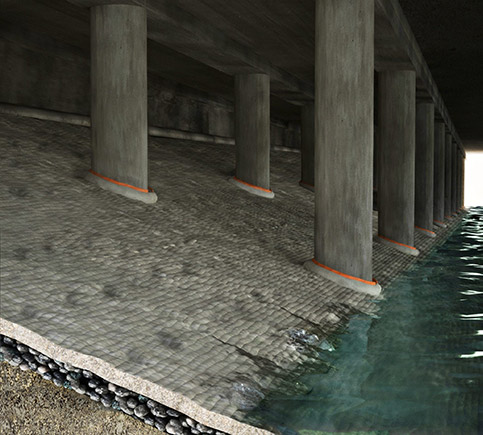

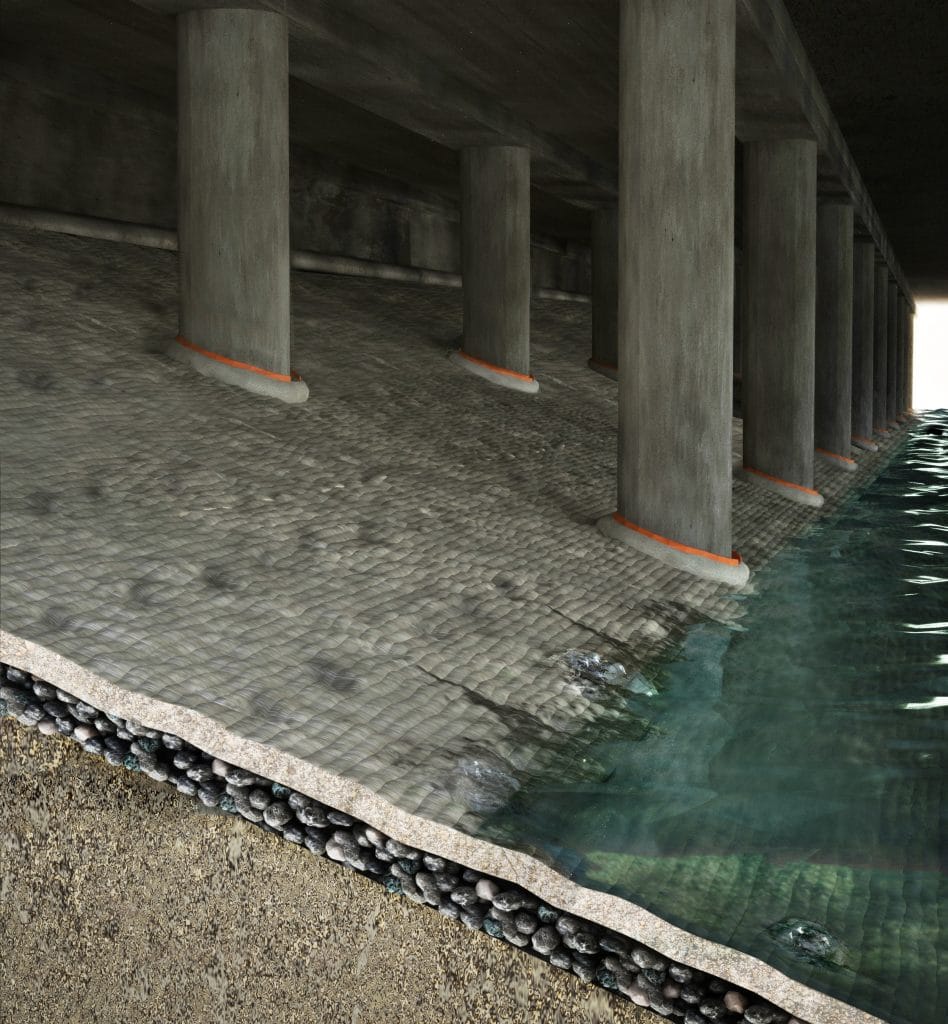

Concrete Mattress Solution

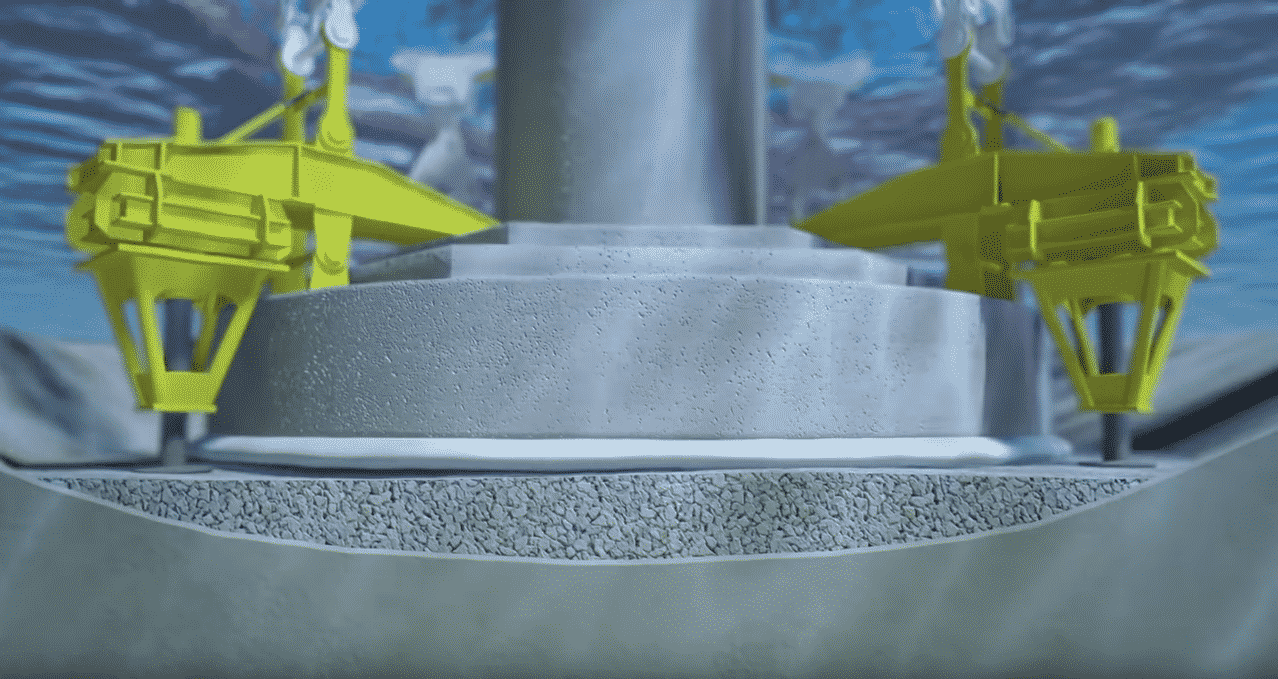

Fabric formed mattress produces a plain concrete slab of uniform thickness with fully interlocking shear joints, producing a continuous concrete slab. This system also forms sand tight seals around the piles, seals to the wall and is embedded or protected with rock at the edges. The impact of the continuous and sealed concrete slab is the efficient distribution of the hydro dynamic forces capable of dealing with low vessel clearance & high propulsion velocity.

In the wave zone the mattress has porosity designed depending upon wave height, this increased permeability allows for effective wave rundown ensuring the integrity of the slab. The slab is typically 220mm thick in the wave zone and 150mm in the submerged area of protection. The system has 35 years of proven usage on piled revetments.

Installation

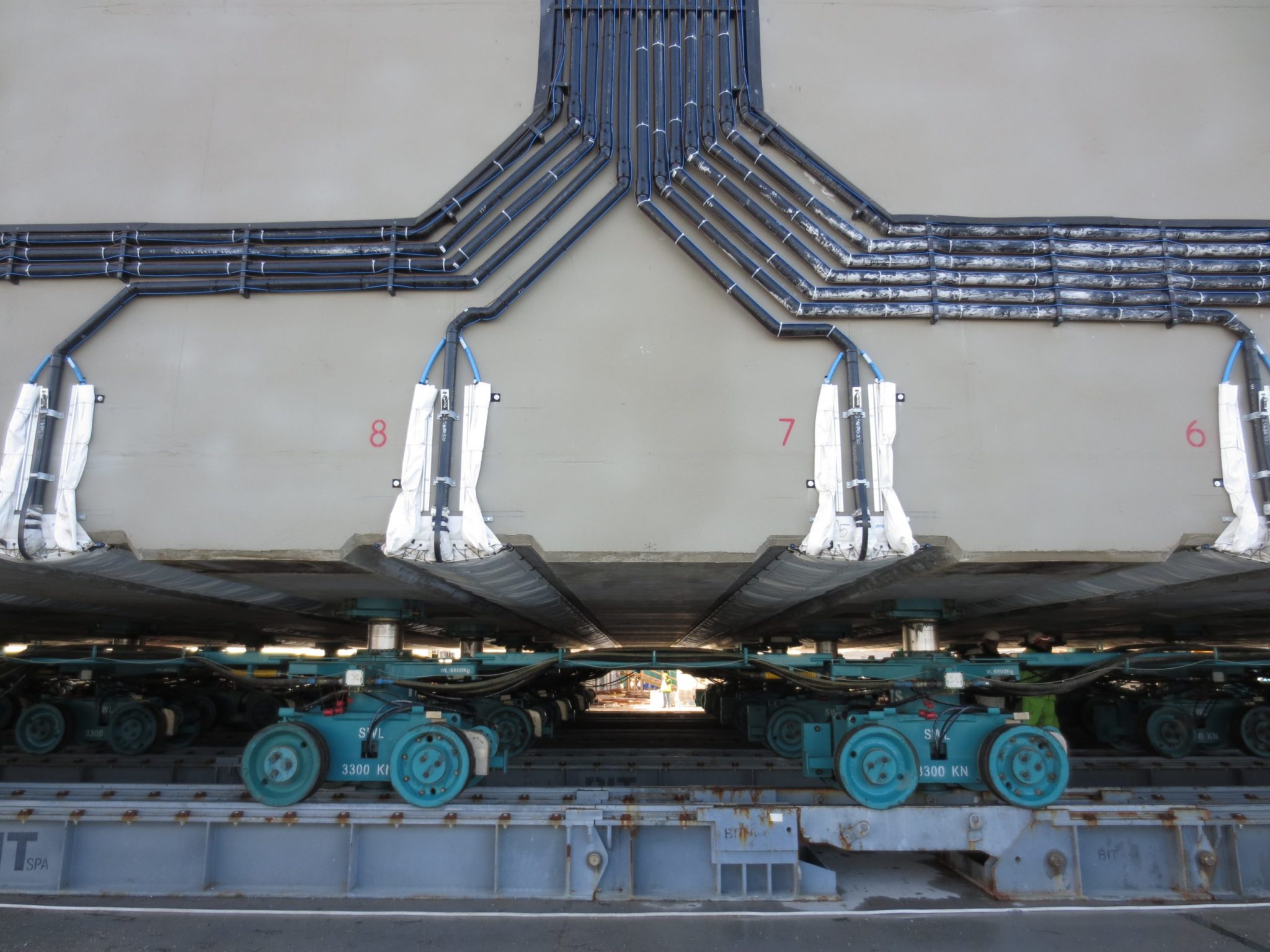

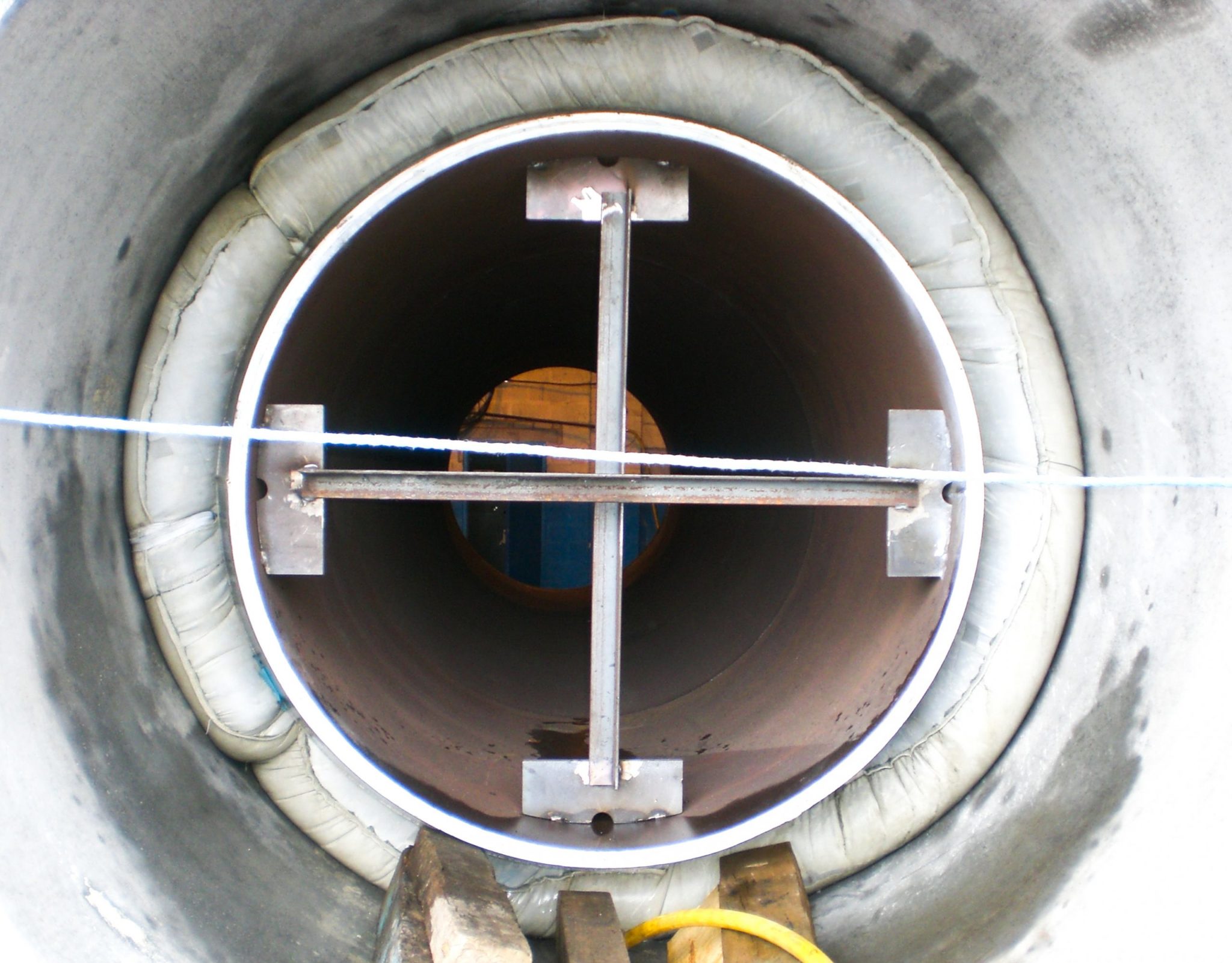

The formwork is tailored to suit each structure, so that a continuous slab and controlled installation are readily achieved. The system can be installed underneath the deck due to the fabric being lightweight to handle before being filled in place. Precise dredging is not required due to the system being filled in situ, enabling the formwork to adjust to the tolerances of the revetment.

The formwork is laid out, fixed around piles, and zipped to neighbouring panels by diver. A 2:1 sand:cement micro concrete mix 35 N/mm² strength is supplied by ready mix wagons and used to pump fill the panels from the bottom upwards using grout hose from the deck above.

Advantages

- Can be installed under the deck ensuring works on above the deck can continue

- Much thinner protection than multiple layers of rock armour

- Expensive marine plant not required for installation

- Better joints and performance than preformed mattress protections

- Copes effectively with revetment tolerances