Requirement

For permanent blocking-off of pipes (such as outfalls, sewers and shafts), a concrete plug/seal can be used.

Example situations:

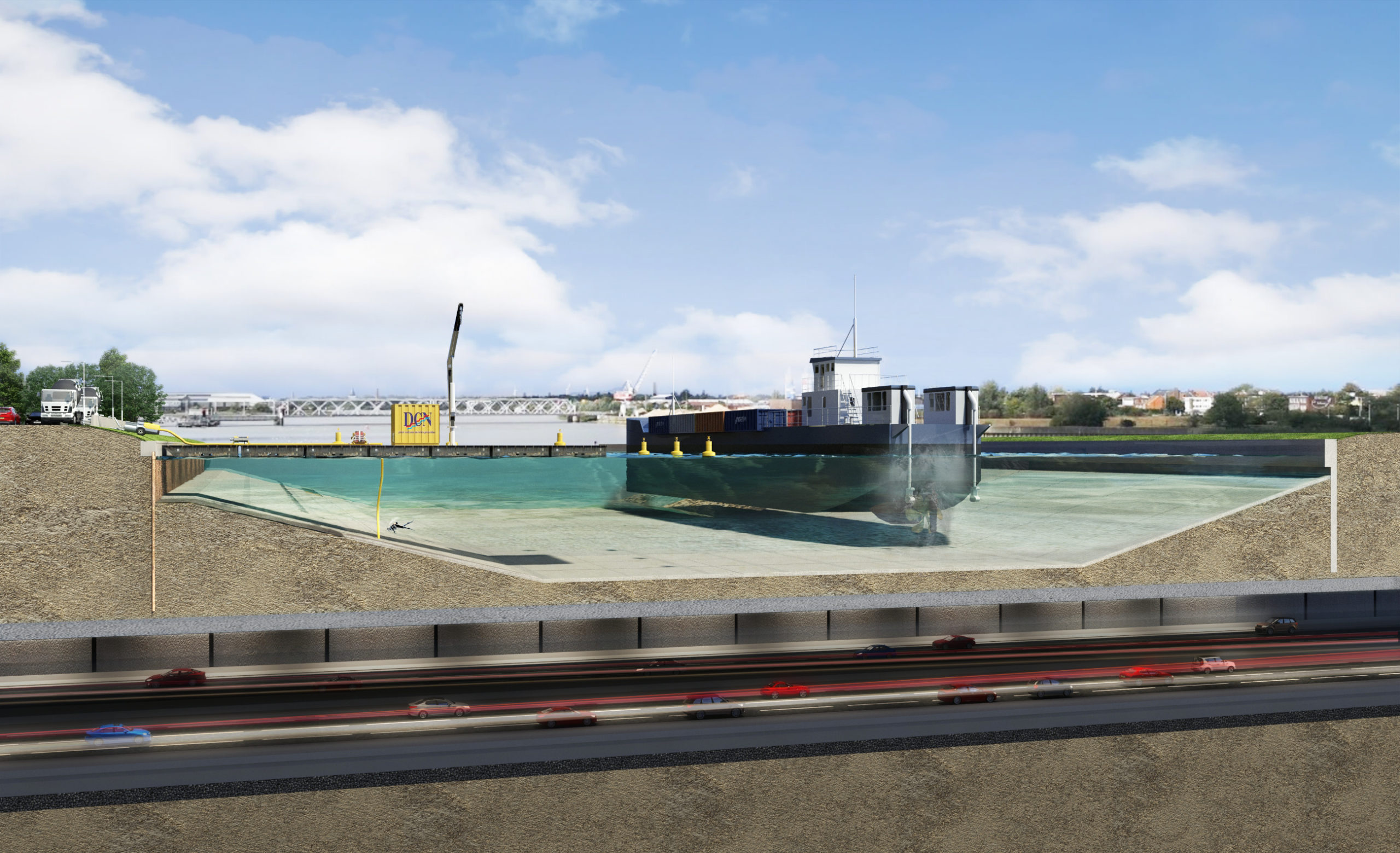

- Plugging of disused sewer pipes, drains or culverts

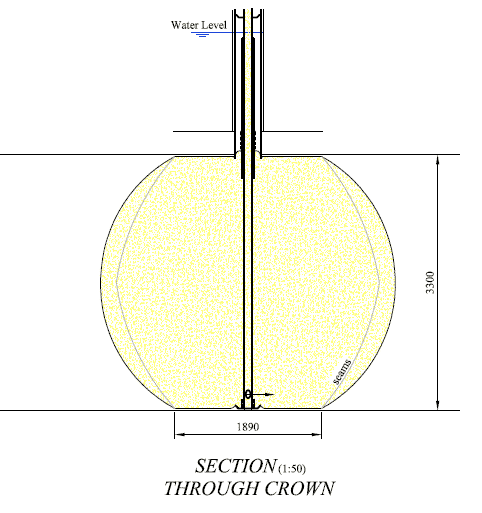

- Plugging a large diameter shaft in two locations, and then mass-concrete infill between (often a lightweight concrete)

- ‘Temporary’ plug to allow further permeant works infill behind

- Sealing an underwater tunnel/shaft by diver

Where a watertight or high pressure seal is required, two forms are often used, and then a non-shrink concrete infill between the two.

Solution

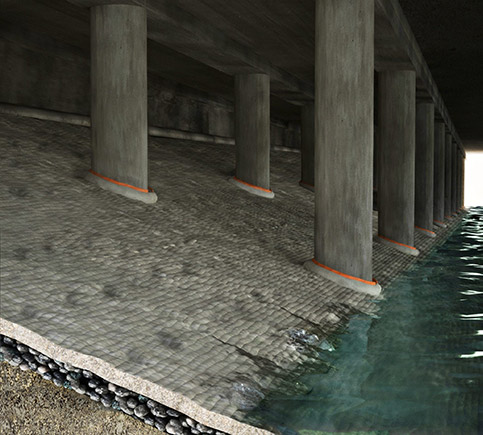

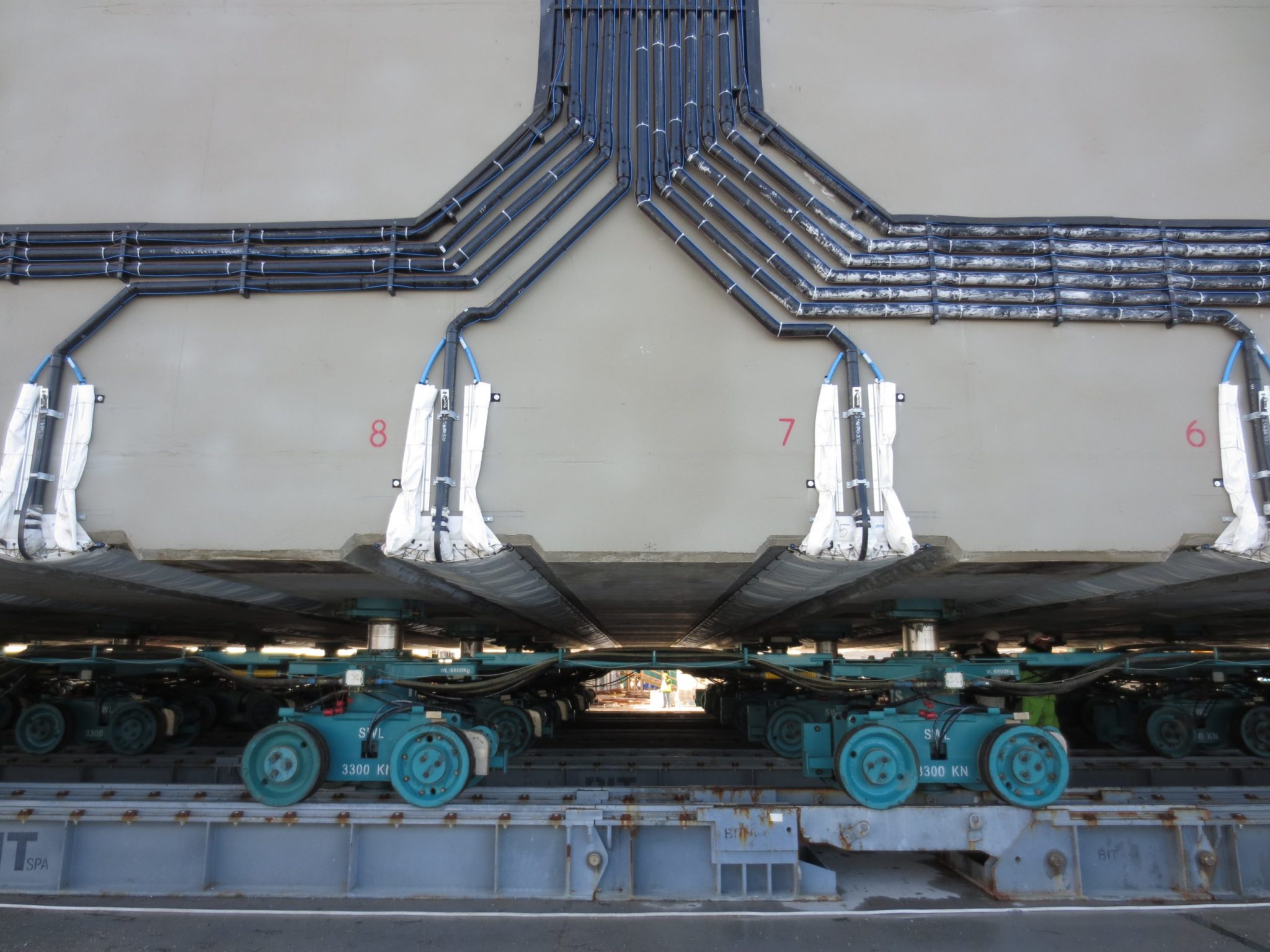

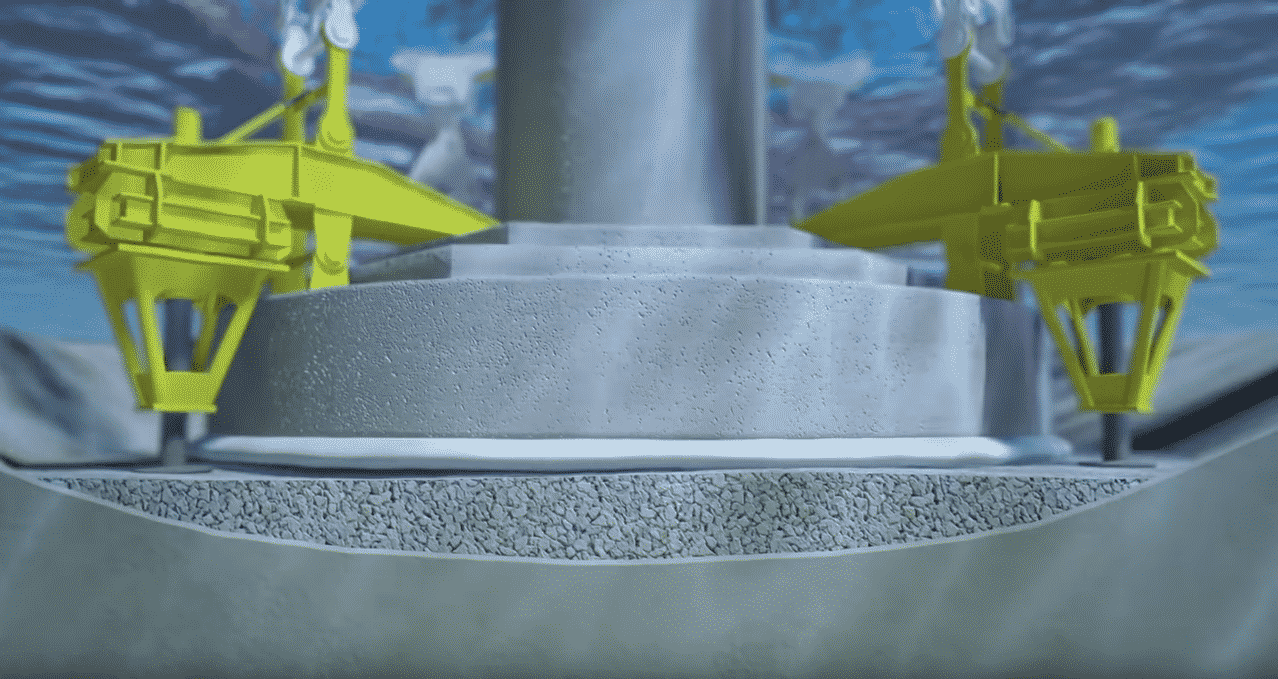

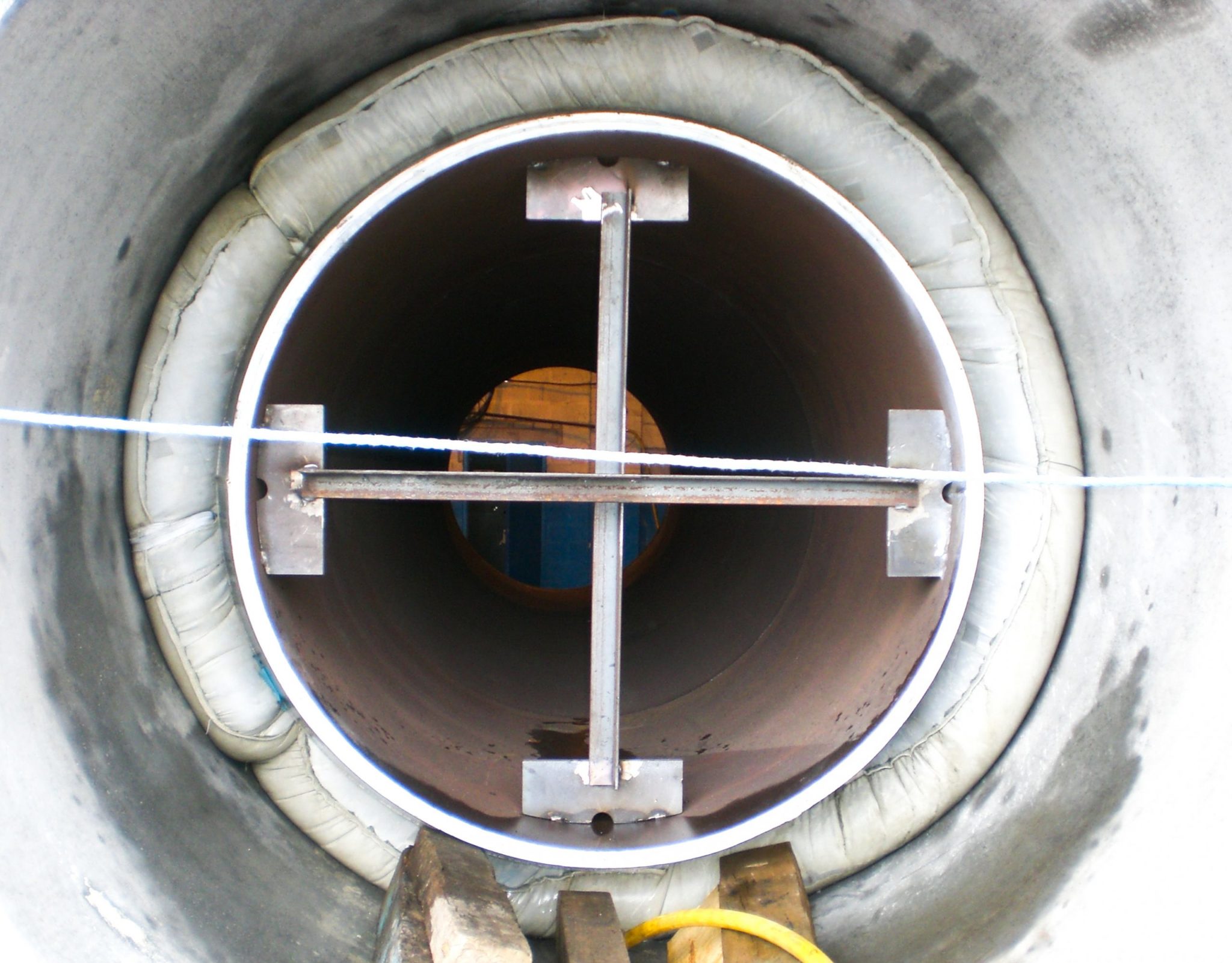

Grouted fabric forms are commonly used to seal or block tunnels and pipes. The forms are purpose designed to suit the size of the shaft plus access and grouting arrangements.

Installation

Seals can be formed in the dry or underwater by divers, pump-filled in situ with microconcrete through small diameter hoses. A vent sleeve is used to control filling pressures and ensure full surface contact.

The lightweight form is usually positioned by hand. Where access is limited, the forms can be inserted via delivery pipe.

Advantages

- Controlled grouting in shafts with access from only one side

- Permanent concrete plug

- Small and lightweight for positioning where access is limited, including underwater

- Pump filled in situ to fit shape of shaft and provide required contact