Grouted Marine Foundations

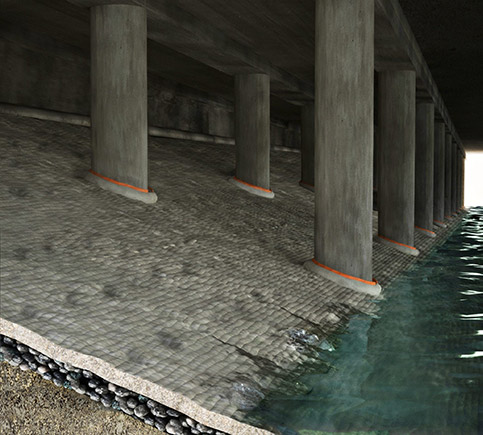

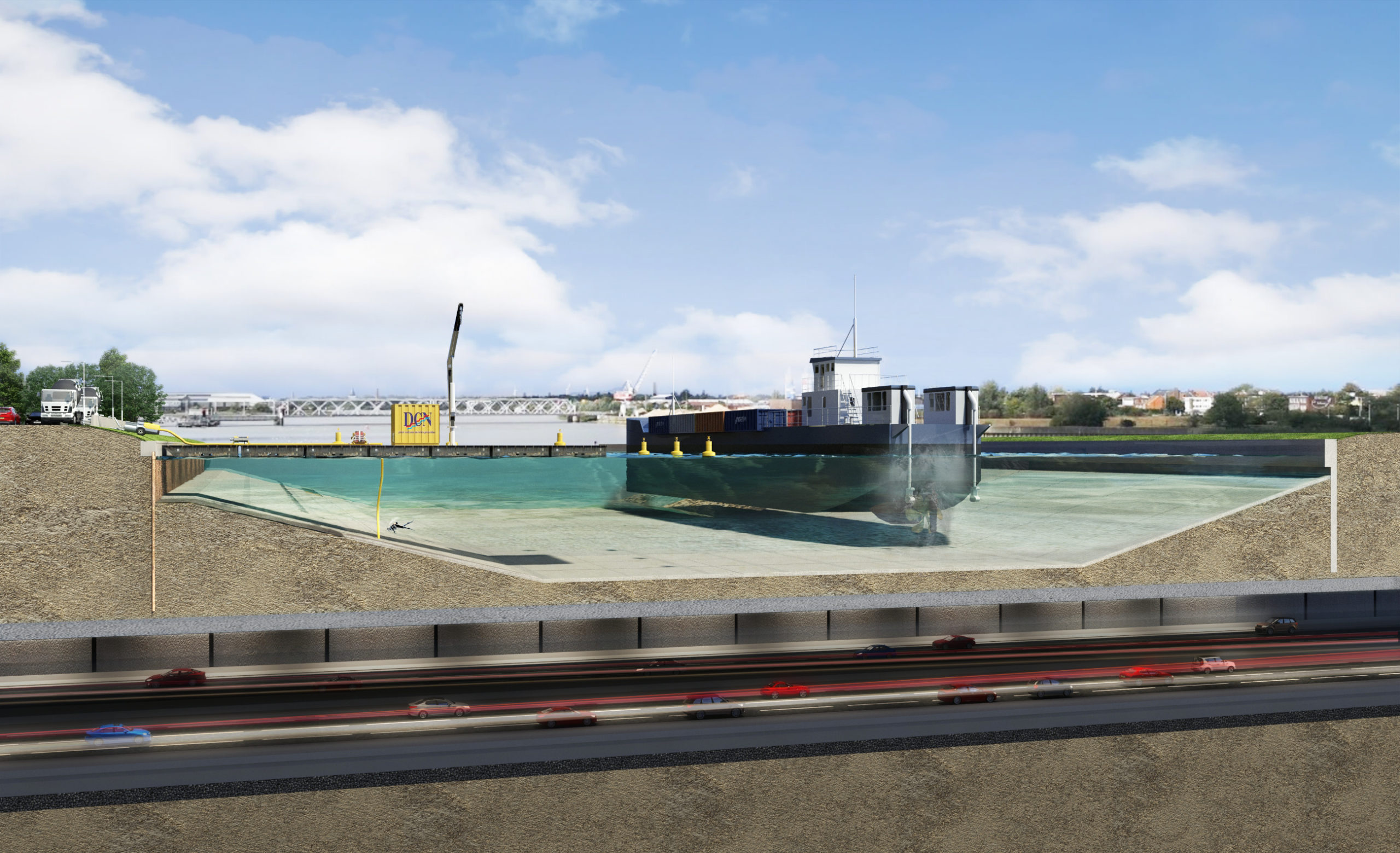

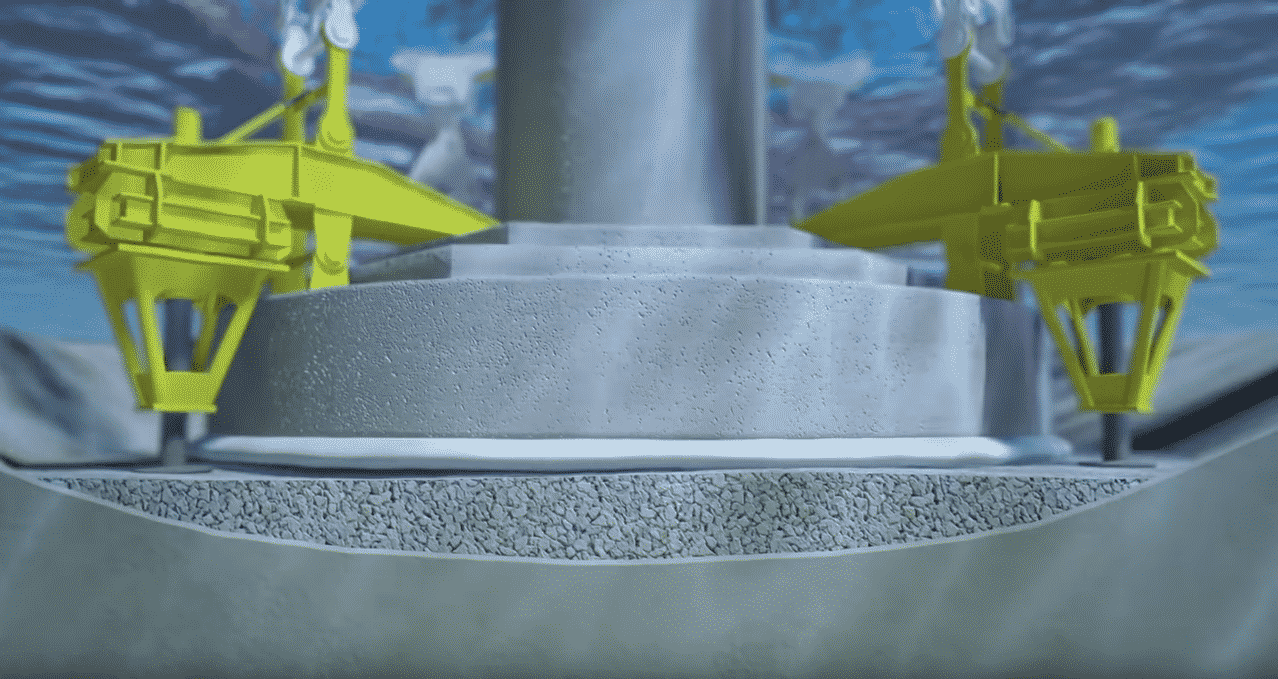

The grout bag system is an alternative to compacted stone bedding layers, providing a grouted layer which fills the void between the precast concrete element being placed and the seabed. Capable of managing a bed tolerance up to 900mm, the system is especially effective when placing elements:

- Onto rock

- In seismic zones

- To avoid accurate stone levelling, settlement and washout

The system has 30 years of proven performance on significant marine projects:

- Caisson Foundations, MOSE Project, Venice

- Sea Bridge Foundations, Coastal Road, La Reunion

- Hard Pad Foundations, Confederation Bridge, PEI

Installation and Grouting

The system is developed in partnership with the designers and contractors to manage the requirements and constraints of each project.

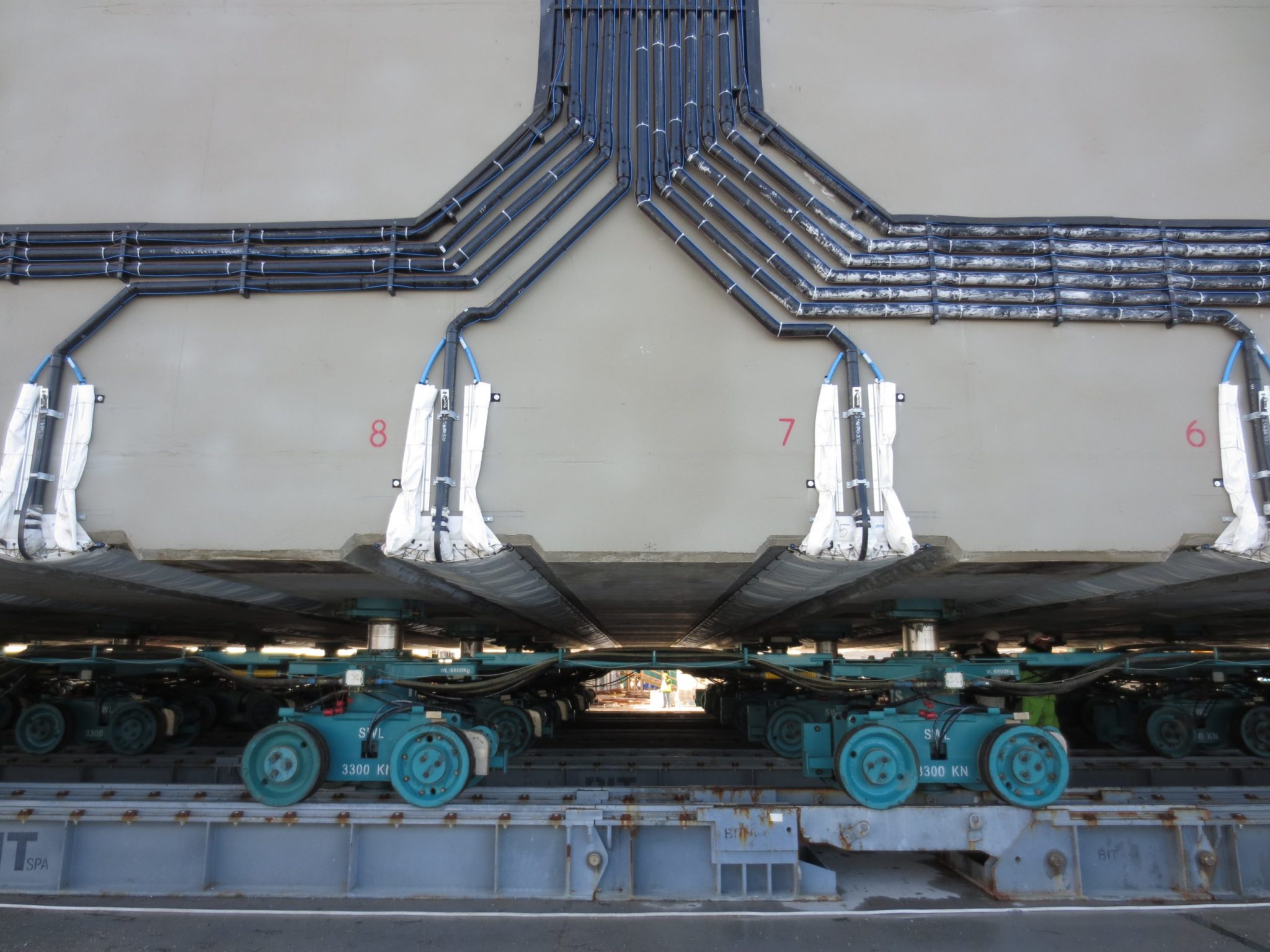

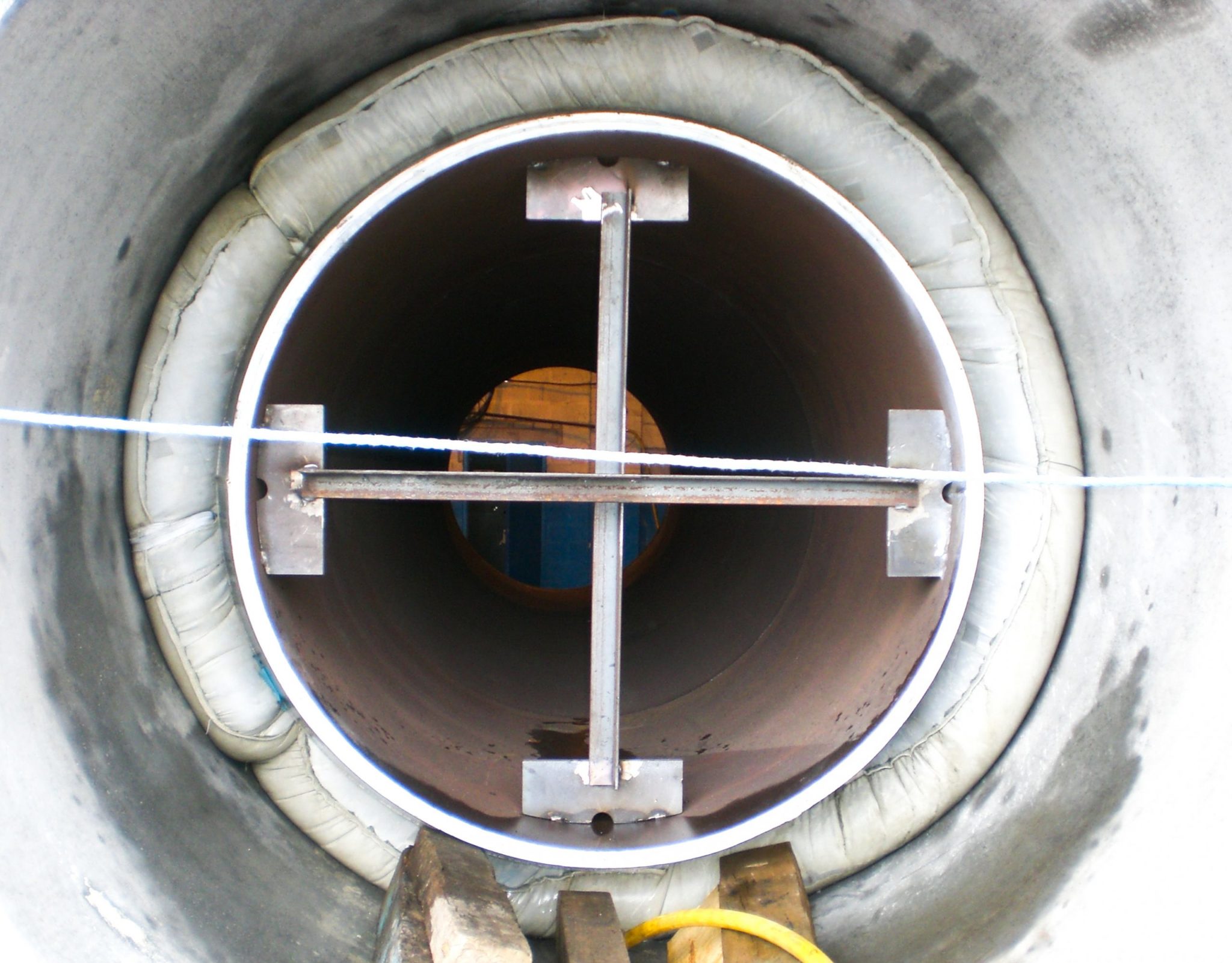

The formwork and grouting pipes are prefixed to the concrete element in the casing yard. Once the element is submerged and positioned on jacks, the bags are pump filled from a grouting barge. The formwork controls the grout, filling the void between the element and the bed surface.

Filling pressure is managed by vents which ensure that the pressure cannot build significantly to fail the formwork or produce unwanted uplift pressure on the element. Once filled, the formwork protects the grout from washout until the concrete has fully set.

Advantages

- Overcome bed tolerances to 900mm

- Eliminating levelling of stone surface

- Avoids washout

- Provides a higher load capacity

- No settlement

- Installed without divers

- Effective in higher flows